Page 1 of 1

For All Eternity

Posted: Wed Aug 26, 2020 10:52 am

by Redleg

I swear that at the end of my life, should my Maker decide to send me to that warmer place, I will spend all eternity seeking the Ford engineer who aligned the Bendix cover screws with the transmission pedal linkage for surely he occupies the darkest corner of that place.

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:02 am

by Rich Eagle

Punch him a couple of times for me too.

Part of your distress comes from trying to do it on a Roadster. A '17 to '22 Coupe is much easier through the suicide door. At least you can get both hands close to the problem.

Best Wishes,

Rich

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:26 am

by DLodge

My understanding is that automotive engineers who are sent to the "other place" are condemned to spend eternity working on the cars that they designed in life.....

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:30 am

by Mark Gregush

I have had the same thoughts when installing the parking brake springs and brake clevis pins on Model A rear end! What were they thinking?

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:35 am

by Steve Jelf

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:39 am

by Dan Hatch

Look for the guy that put the oil cooler on the 460 in motor homes. That looks like someone’s after thought. Short hose , bigger round that long with no space to install it.

Maybe same guy did bypass hose on 390 too.

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:47 am

by RustyFords

He'll also be with the Honda guy who made it necessary to remove the right front suspension, front bumper and radiator on an Odyssey minivan in order to change an alternator.

It'll be a large room/lava pit/cauldron...there'll be a guy from Jaguar in there with several others I can think of.

Re: For All Eternity

Posted: Wed Aug 26, 2020 12:00 pm

by HPetrino

I had an Acura TL, 2004 if I remember correctly. A headlight bulb burned out. Per the manufacturers published instructions the only way to change that #@%&@ bulb was to first remove the entire front bumper cover, then dig your way in from there.

Re: For All Eternity

Posted: Wed Aug 26, 2020 2:17 pm

by Norman Kling

That is easy if you start the bolt nearest the transmission first and then slide on the bendix cover. The other screws are harder than that one. Another such problem is the nut on the crankcase ear which goes through the wood block and frame on the same side as the starter. I have found the easiest way for me is to use a box end wrench with masking tape around the socket and then press the nut in place. Then crawl under the car turn the bolt from the outside while manuvering the nut around until the thread starts to engage. Then the cotter pin must be inserted with a long nose pliers. I only bend the end of the cotter just enough to keep it from sliding out if the nut spins with the pin down. This too is harder on a car without the drivers door.

Norm

Re: For All Eternity

Posted: Wed Aug 26, 2020 2:39 pm

by FordFool

I put Allen heads in mine. Use a ball end wrench. No problem. Don

Re: For All Eternity

Posted: Wed Aug 26, 2020 3:00 pm

by John Warren

My father always said that if the engineers had to change it before they could have their supper, like he had to, it would have been designed differently. A split screw driver ( Kline K23 ) makes those screws much easier, as long as the screws have a decent slot. Usually you will find these screwdrivers in the electrical tools.

- split screw driver.jpg (13.97 KiB) Viewed 5677 times

Re: For All Eternity

Posted: Wed Aug 26, 2020 4:32 pm

by Bill Robinson

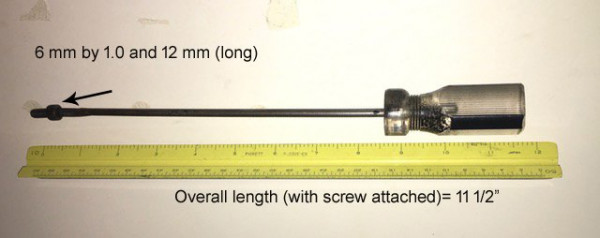

- Allen Screw Driver- thanks to Reid Welch's post

Back around the turn of the century there was an active forum member named Reid Welch from somewhere in Florida. A thread was started regarding the pain of installing and removing the slotted bendix screws. Pictured below is Reid's answer. The picture is my donated screwdriver that I cut off and welded a short 1" piece of an allen wrench to the screwdeiver shaft. Once the driver is inserted into the allen screw it stays put and allows you to wiggle the screw through the shafts and align it with the threaded hole, horizontally. Overall length is very important. I have used the screwdriver many times over the years on my T's and helping many friends. It's still working now....and For All Eternity.

Re: For All Eternity

Posted: Wed Aug 26, 2020 5:41 pm

by DanTreace

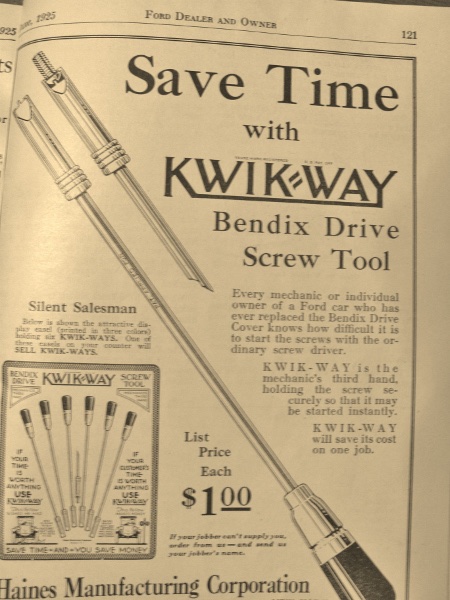

The good thing about design engineers mistakes, it make a nice business for making solutions and making money on inventions!

Period adv. for those pesky Bendix screws.

- IMG_3720 (450x600).jpg (134.28 KiB) Viewed 5592 times

Choice tools in the T tool box, small screw holding screwdriver with release sleeve. Plus an old time one. The extra long single slot is used to finish the tightening, or for removal, as it reaches easy past the brake pedals and cams.

Re: For All Eternity

Posted: Wed Aug 26, 2020 6:47 pm

by Dan Hatch

Split screwdriver??

That is what we all called “Monday Morning Screwdriver “

If I have to explain, you won’t understand. Dan

Re: For All Eternity

Posted: Wed Aug 26, 2020 7:00 pm

by StanHowe

They are 14-24 thread screws. Next time you are ordering something from McMaster Caar or MSC, order box of 14-24 FILLISTER head screws. Makes it a lot easier to keep them on the tip of the screw. Take a nice long screwdriver, grind the tip until it will just start in the slot, tap it in the slot with a lbbfh so it holds the screw on the tip and go to work. Makes a miserable job maybe not easy but not that bad. Cost you about 5 bucks for a box of 25. Makes it a lot easier to get them out, too.

Re: For All Eternity

Posted: Wed Aug 26, 2020 7:52 pm

by Allan

John, it's not the engineer's fault. Blame it on Henry for his contrary decision to make his T models Left Hand Drive. We have no problems where the wheel is on the right side

Allan from down under.

Re: For All Eternity

Posted: Wed Aug 26, 2020 8:21 pm

by Bill Dizer

Post WW2, it's will it go down the assembly line, and will it make it out of warranty! After that you are on your own! Try an oil pan on a late 90's s-10 blazer, bravada, jimmy 4x4! Front axles, right side axle extension, front differential, oil cooler lines, flywheel cover, starter etal! Or Pontiac grand am water pump on the 4 cylinder engine on the rear below the exhaust manifold, run by the timing chain! Or another favorite, 86 up Ford Taurus heater core! Drain a/c, pull entire steering column down, loosen entire dash, remove heater box. 9 hrs or so book time, much much less after you have done some, and know the tricks!

Re: For All Eternity

Posted: Wed Aug 26, 2020 11:50 pm

by StanHowe

The two things that made me sell my 62 T bird convertible were 1. The windshield wiper motor is accessed through the radio speaker hole. It is recommended to REMOVE THE WINDSHIELD for better access. If I was ever going to do it again I would have to lose 50 lbs, take agility training for 6 months and then have knee pads that allowed me to access the wiper motor with one hand while turned away -- facing the rear of the car -- and taking the 5 nuts off that have to be removed to pull the motor up out of the speaker hole. I would remove the windshield and the hood or sell the car if I ever had to do it again.

2. Heater core. Instruction one: Remove the dash assembly from the car. It took me two days to get it out, replace the heater core and put the dash back in it. In about 1995 or so I was quoted $600 by a shop that worked on them. I would pay it in a heartbeat. A heartbeat!!!!! There is a panel that can't be removed -- since it is a unit body -- that runs from side to side and everything is accessed through the holes in that panel.

I did this about a month after I replaced the wiper motor.

Somebody in California bought it when I sold it at Barrett Jackson, I cashed the check and drove a 47 Chevy Fleetline sedan home from Arizona. I've only owned one other car I was happier to see gone than that T Bird. (A Subaru Outback) The top mechanism????? I was the world expert after three years with that thing.

Re: For All Eternity

Posted: Thu Aug 27, 2020 12:02 am

by Alan Long

I agree with Allan from Gawler, never had an issue with Pedals or Linkage while working on the Starter! Our issues

are starter Buttons melting, and the steering column getting in the way of Timers, Generators and Fuel lines.

Even back in my days working at Borg Warner we had vast differences with our product from state to state.

Hilly NSW used to have Torque Converter failures and WA broken differential tubes.National meetings about issues

were very interesting. Alan in Western Australia

Re: For All Eternity

Posted: Thu Aug 27, 2020 1:13 am

by Vic_alberta_Canada

Fancy screwdrivers! as a retired electrician we always just whittled a stick to hold and start the screw!

Re: For All Eternity

Posted: Thu Aug 27, 2020 6:11 am

by Allan

My trick may work with the screwdriver you already have. Fit a short length of rubber fuel line over the end of the screwdriver. Plug the screw into the end of the fuel line to hold it in place and screw away as you like. Easy-peasy!

Allan from down under.

Re: For All Eternity

Posted: Thu Aug 27, 2020 12:18 pm

by cessna53195

The fact that these screws are #14-24 usually means they are the original ones and quite often the slot is pretty worn out. A tinkering tip I have used before is the toilet bowl wax ring I have on the work bench. Just put a wad of wax on the end of the screw and it will hold right on...Wax ring is great to lube the springs, threads, oil lamp locking slides, head light rims, wheel rims just use your imagination. Another positive is it is friendly with paint...every work bench needs one...Robert