Page 1 of 1

Crankshaft Balancing...

Posted: Mon Dec 28, 2020 6:51 pm

by Tim Rogers

For people in the know- should the crank and flywheel be balanced separately and then balanced again as an assembly or just balance the assembly only?

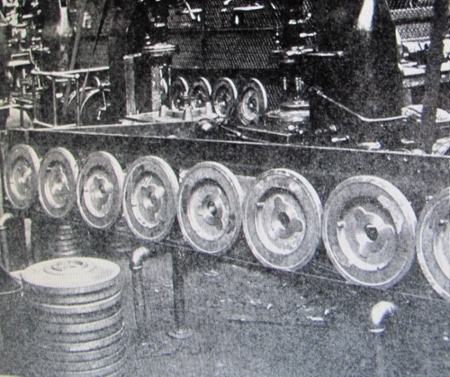

- balance.jpg (9.8 KiB) Viewed 6585 times

Re: Crankshaft Balancing...

Posted: Mon Dec 28, 2020 7:01 pm

by Dan McEachern

Crank separately, flywheel separately, trans drums separately. You can balance all your pieces EXCEPT the crank on that balancing stand because you can balance those pieces as a single plane rotor and a static balance will suffice. That is not the case for the crank- it needs to be dynamically balanced on a spin balancing machine.

Re: Crankshaft Balancing...

Posted: Mon Dec 28, 2020 7:03 pm

by Henry K. Lee

Dan Knows!!!!!!!!!

Hank

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 9:19 am

by J and M Machine

Tim Rogers wrote: ↑Mon Dec 28, 2020 6:51 pm

For people in the know- should the crank and flywheel be balanced separately and then balanced again as an assembly or just balance the assembly only?

balance.jpg

As Dan mentioned the parts have to be balanced separately and don't forget to weigh the triple gears as most often they are off.

As seen in the pictures we dynamically "spin" crank and flywheel transmission drums and make corrections. We static balance "Weight match" the rods pistons and triple gears. Balancing the engine makes a big difference as most often the rods are way off along with flywheel since there's no way to keep weight of the magnets even. Balancing takes care of the out of weight situation and also makes the car so much better once done properly.

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 12:59 pm

by jiminbartow

When determining the magnet to coil gap, the gap at the bottom is smaller than the gap at the top, due to the sag caused by the weight of the transmission on the end of the crankshaft. As the engine spins, I would assume this sag is one of the sources of the vibration inherent to the T that we all experience. How is this sag dealt with in attempting to balance the various components of the engine?

The babbited fourth bearing (ball cap) was designed to support the heavy transmission drive plate end shaft. When I rebuilt my engine in 2010, I sent my ball cap and drive plate off to George King III in Connecticut for him to re-babbit the bearing and machine the drive plate to fit, so I had a very close fitting drive plate that provided good support to the transmission, but even with a close fitting drive plate shaft, there was still somewhat of a sag to contend with when setting the magnets/coil gap. On T’s with the normal amount of drive plate to ball cap bearing wear, I’m sure the sag and resulting vibration is much more than on my T with its’ rebabbited fourth bearing and fitted drive plate and I find it difficult to imagine how this can be addressed in the balancing of the various components. Even with everything else perfectly balanced, as long as the sag remains, I don’t see much chance of eliminating the vibration. Jim Patrick

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 2:57 pm

by Steve Jelf

...there's no way to keep weight of the magnets even.

Is there anything wrong with picking magnets that are all within a few grams and grinding a little off the ends of the heavier ones to equalize them before you charge and install them?

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 3:22 pm

by Jerry VanOoteghem

Steve Jelf wrote: ↑Tue Dec 29, 2020 2:57 pm

...there's no way to keep weight of the magnets even.

Is there anything wrong with picking magnets that are all within a few grams and grinding a little off the ends of the heavier ones to equalize them before you charge and install them?

There's probably nothing wrong with that, but why bother? When they're installed on the flywheel, and the whole thing is balanced as a unit, it becomes irrelevant what each magnet weighs. It's all compensated for in the unit balance.

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 5:31 pm

by Allan

Steve, it can't do any harm. If your flywheel is dise\-assembled to check the magnets for cracks or to set the magnet keepers heights, matching the magnet weights is an easy job, but it does not need to be to the same degree of accuracy as other operations. The same goes for selecting a closely matched set of rods prior to re-babbiting them. The same goes for triple gears. It is easier to match rebushed gears if you start with reasonably close weights.

Allan from down under.

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 5:46 pm

by J and M Machine

Steve Jelf wrote: ↑Tue Dec 29, 2020 2:57 pm

...there's no way to keep weight of the magnets even.

Is there anything wrong with picking magnets that are all within a few grams and grinding a little off the ends of the heavier ones to equalize them before you charge and install them?

Hello MrJelf:

There's nothing wrong with that. HOWEVER: my time is your money so how would you like me to spend it?

My machine takes about 5-10 minutes at most to balance a flywheel assembled .

How long would you figure it takes you to weigh all the magnets and then grind them individually to get to the same equation?

The same context as you making the washers to shim the magnets to achieve the same heights. Nothing wrong doing it your way.

I'm not knocking you as you're doing it the way you like but naturally I have to do it as fast as i can to make it worthwhile as we are in business.

Re: Crankshaft Balancing...

Posted: Tue Dec 29, 2020 10:34 pm

by Steve Jelf

Thanks, John. That makes perfect sense.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 11:52 am

by Dan McEachern

To add to all that, when you get all the magnets weighing the same, get it all assembled, you still have no guarantee that the assembly will be even close to being balanced, as most flywheels have some pretty significant factory balance holes in them from the original factory balancing that compensated for all those unequal weight magnets.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 12:24 pm

by henryford2

Just to add my two cents worth, the allowable amount of unbalance (residual) for specific applications can generally be found in several ISO standards. The physical shape of the part will often determine if the balance should be static or dynamic. With that said you can balance each part of an assembly to an acceptable range, only to have the total assembly out of balance. In my experience (not at the same level as Dan's) it becomes a case where the residual unbalance of the individual parts fall on the same plane (location). A blower assembly may vibrate (both the motor and blower wheel are balanced), but simply rotate the blower wheel on the motor shaft (no "D" shaped shaft) and the vibration may go away. So after all that, I've said pretty much the same thing as Dan, balancing the magnets may not produce the results you're looking for. Just my humble opinion, stay safe.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 4:02 pm

by J and M Machine

Here's a perfect example of the flywheel being Way off.

This is a 1914 we did .

It was off @ 134 grams almost 5 ounces per inch of the diameter of the flywheel.

Looking at it the total amount off was 1010 grams/ 2.2 pounds in total unbalance.

Combined weight of unbalance of the magnets and flywheel and also the plates.

After i drilled the two 1" holes I was able to get the total balance at two hundreds of a gram per inch and a total of tenth of a gram.

Better than it has to be but closer I get it, the better car runs and lasts.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 5:00 pm

by Allan

The bit which I find hard to understand is Ford balanced the flywheel before the magnets, keepers and screws were installed. I have no idea how this was done or how accurately. Perhaps it was just perfunctory to get things a little closer to some state of balance. Sure, modern equipment can do the job well on a fully built up flywheel assembly, but if you have the magnets off for inspection and individual charging, it make some sense to me to even up the weights before re-assembly. Then perhaps the amount of material needed to be removed to achieve balance will be considerably reduced.

Allan from down under.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 7:23 pm

by dykker5502

A wheel is a wheel and I have now balanced 3 flywheels in a regular wheel balancing machine with succes. Here is the latest.

alignment controlled:

Of course the scale is not correct and you must remember when it says to add 5 grammes you should REMOVE material (not necesarily 5 grammes) from the opposite side of the wheel.

I believe it make it within 1 gram.

Re: Crankshaft Balancing...

Posted: Wed Dec 30, 2020 8:01 pm

by Roz

I have a question for the balancing pros. I always have the flywheels dynamically balanced. I don’t know he how holds them in his machine, but I assumed it was on some sort of mandrel. It seems to me there might be a significant difference between locating in the center bore like the crank flange is located and locating off the chamfer around that hole. I just assembled one that I noticed the chamfer was way off center. I made sure to point that out to my balancer guy when I dropped it off. He said no problem. My lathe is not big enough to true it up with the center bore or I would have. I don’t know how he locates them, but I’m going to ask when I pick it up. How should it be located on the machine?

Re: Crankshaft Balancing...

Posted: Thu Dec 31, 2020 1:05 am

by Dan McEachern

John showed a picture above of a pretty standard flywheel mandrel. The flywheel is radially located on the mandrel by the cone as shown above. The cone angle is steep enough that it contacts the edge of the bore in the flywheel- not the chamfer on the bore. BUT, as Dennis asked above, it is always good practice to indicate the inside diameter of the counter bore that locates the flywheel on the crank flange during setup, to make sure it is running true. To add to this, any clearance between the crank flange OD and the ID of the flywheel counterbore can introduce additional runout at assembly.

Now another fine point- did the crank grinder indicate the flange OD when the main journal was ground? As you can see, all the little details start piling up pretty quickly.

Last comment- balancing machines with modern electronics are amazingly sensitive- down to the point where you can chase a perfect balance using an 1/8" drill bit and the balancer will see the change in unbalance. It almost becomes a game where you want to see how "perfect" you can get it even after the machine is telling you that you are in spec for a given unbalance amount. Not so easy to do with older equipment. We upgraded our balancer about 4 years ago, and the difference was amazing- but not inexpensive.

Re: Crankshaft Balancing...

Posted: Thu Dec 31, 2020 3:13 am

by Allan

Dan, I missed your earlier post re the factory balancing to counter the out of balance of the magnets etc. As the factory drillings are under the magnets, I supposed that factory effort was just to get the flywheel somewhere near balance. There seems to be no way the factory drillings are used to balance the assembled flywheel. Or, have I missed something?

Allan fromdown under.

Re: Crankshaft Balancing...

Posted: Thu Dec 31, 2020 11:44 am

by Dan McEachern

Hi Allan- you may be correct on that point, but I have never balanced a stripped flywheel that was anywhere near being in balance and not needing correction. My only point was that weighing the magnets for equal weight does not replace balancing the entire assembly. Thanks for pointing out something that I may have overlooked.

Re: Crankshaft Balancing...

Posted: Thu Dec 31, 2020 6:57 pm

by Allan

Dan, I have never even checked the balance of a naked flywheel with its factory drillings. Perhaps I should in future, purely out of interest. I have assembled flywheels balanced by a local machine shop. If I have a flywheel assembly torn down, I do make some attempt to match the weight of the magnets after any suspect ones have had the anvil crack test! I figure that if the weights are somewhat consistent, there should be less to do to bring the whole assembly into balance.I agree with a previous poster that it is not worth the effort to r=tear down a flywheel assembly just to match weigh the magnets.

Allan from down under.

Re: Crankshaft Balancing...

Posted: Thu Jan 07, 2021 10:19 pm

by Dennis Prince

A question for those in the know, a few of us in our group just acquired a crankshaft balancer and unfortunately before we could get any instruction on it the fellow we got it from passed away, I have been able to figure out how to set it up and make it work but it came with a Vibration Displacement Indicator and I have no idea what it does or how it works. I have found some for sale on the internet but no info on how it works or how to use it. Any help would be greatly appreciated.

Re: Crankshaft Balancing...

Posted: Thu Jan 07, 2021 11:19 pm

by dykker5502

FWIW - I do not think Ford balanced the flywheel until relatively late in the era. The first T flywheel I did was a 1927 engine which had some drillings (I have had all the magnets off and not marked them to put them back the same places). The one on the pictures above is from a march 1925 with no drillings what so ever.

Re: Crankshaft Balancing...

Posted: Fri Jan 08, 2021 11:04 am

by DanTreace

Michael

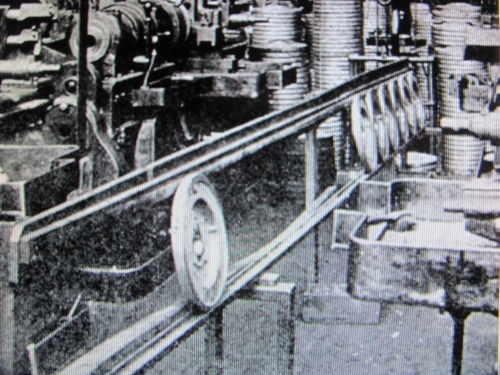

Ford balanced the flywheels, Ford Methods and Ford Shops (1914-1915) lists the 16 mfg. (machining) steps from raw casting of T-701 gray iron weight of 41 lbs. to finished 35lbs. The last step is noted "16. Balance on Rockford Tool Company's balancing machine." No photos of that operation, but the flywheels were in some type of balance.

- IMG_9010 (500x419) (500x419) (450x377).jpg (127.93 KiB) Viewed 5304 times

- IMG_9011 (500x375).jpg (129.43 KiB) Viewed 5304 times

Re: Crankshaft Balancing...

Posted: Fri Jan 08, 2021 1:12 pm

by dykker5502

Nothing that can destroy a good discussion like documented facts

However - I've seen flywheels with no drilling but which where not balanced to the precision we can do today. One explanation can be that the magnets most likely was not put back in the same order.

Re: Crankshaft Balancing...

Posted: Fri Jan 08, 2021 2:52 pm

by DanTreace

Thanks Michael

Yet to see a flywheel w/o blind drill holes or wide smooth grind marks on the flat surfaces indicating balancing at the factory.

This is 1924 engine flywheel, single hole.

Re: Crankshaft Balancing...

Posted: Fri Jan 08, 2021 5:16 pm

by Dennis Prince

Re: Crankshaft Balancing...

Posted: Fri Jan 08, 2021 6:36 pm

by Scott_Conger

Dennis, check your email inbox or spam