Page 1 of 1

Lost a tooth!

Posted: Mon Jan 18, 2021 12:35 am

by Thorlick

My granddaughter was excited to find a 50 cent piece under her pillow yesterday following the loss of an incisor. This got me motivated to start repairs on Rusty my 1927 roadster pickup. My daughter had taken a nice young man out to teach him to drive the T. The fact that things went south when he was driving is solely coincidental.

Today I pulled and opened the engine retreving a tooth from the oil dips. Taking a cue from Eilonwy I am putting the tooth under the seat cushion... I expect to find a complete Livingood FWD set-up there first thing in the morning!!!

I don’t know how I will be able to sleep waiting for the great event!!!!!

- First tooth lost!

Oh, forensic evaluation lays the blame on a worn triple gear bushing, not the “cute guy”.

TH

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 8:29 am

by perry kete

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 10:47 am

by Norman Kling

Thanks for the picture! I was wondering how someone could lose a tooth and have it end up in the dips!

Norm

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 10:54 am

by Adam

That broken tooth obviously didn’t DESTROY your transmission. Frankly I can’t imagine having any better luck! Don’t drive it until it is properly repaired.

There are so many variables where the transmission and triple gears are concerned that it can be very hard to reason out exactly what occurred.

A couple key things I would look at when rebuilding is:

-Check the triple gear pins to make sure they are absolutely parallel to each other.

-Check the “circle” of the pins and make sure they are perfectly concentric with the transmission shaft installed in the flywheel.

These are two key areas that could cause one gear to load heavier than the rest.

Barring any other “obvious” thing you find, a failure could just be due to fatigued 100 year old parts too.

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 11:53 am

by Bud Delong

It's good to see your post TH!! Bud.

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 11:56 am

by Thorlick

Adam,

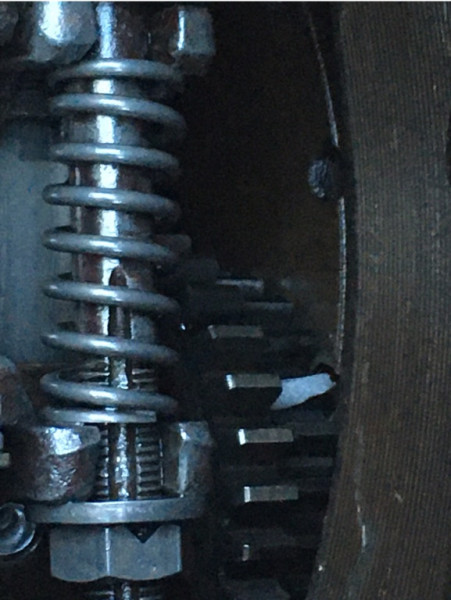

Some parts are 100 some not so much. About a year ago I went through the transmission. The ancient riveted triples got new bushings, two got the new expensive alloy bushings. The third got an old reproduction bushing I had on the shelf, I suspect old alloy formula. I drive the car a lot and hard but what I found was that two triples are nice and tight... possibly still near .003" where I reamed them. The other has egged out the bushing, it wobbles and flops all over... it has a broken tooth which you can see has no oil on the severed spot... I guess it is the cheap alloy bushing triple. The gear broke and jumped a tooth at the same time locking up the transmission. If you can get a transmission together with a gear out of time you will know that all three drums lock up. That is what my transmission did.

A friend was here and he went fishing when I split the case. I was busy getting the engine onto the stand and didn't see where he found the tooth. He is a great fly fisherman and doesn't tell where he has the best catch... he failed to mention where the tooth was, I'll try and find out today. I was most likely wrong about the dips (a little poetic license?), it was probably at the drain plug teacup.

For the life of me I don't yet know what wore the bushing out so fast. The next issue is that the new turbo 400 clutch drum had a square head bolt holding it in place. It is a steel drum not the pretty bronze I have used before. I remember there was difficulty inserting that bolt and it didn't go in all the way. It sure as heck didn't come out either. We both worked on that for hours..

- broken clutch drum bolt... yep, I did that!!!

The tranny and flywheel are now up on my mill preparing to have the clutch drum cut off. Once that is done I will be able to remove the transmission and inspect the triple gear pins... which look good whilst sighted through the drum webs.

Now the real tragedy in all this: there was no Livingood under my seat cushion this morning, just an oily busted tooth. This means that the Tooth Fairy is at home self isolating and recovering from the Covid... I wish him/her well and a speedy recovery... and that the Livingood makes a belated arrival!

Terry

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 12:41 pm

by Thorlick

Perry,

Two Terrys?

- NOT toothless!

TH

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 2:44 pm

by TeveS-Nor Cal

I have gears in stock!

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 4:35 pm

by Norman Kling

It could very well have been something else in the engine or transmission which got caught in the triple gears, and not the bushings causing the problem. On one of my T's one of the bolts which hold the drive plate to the brake drum came off and went to the sump which got caught by the flywheel and stripped the starter gear. The hole in the brake drum was cracked and the bolt came out.

Norm

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 8:25 pm

by Thorlick

Adam,

You said That broken tooth obviously didn’t DESTROY your transmission. Frankly I can’t imagine having any better luck!

Right now I am looking for a geiger counter. It is the only way I can assess the nuclear bomb that went off inside Rusty! Some of it can be seen in this little instructional video I have posted:

https://www.youtube.com/watch?v=wdWnz_lJveY

That broken clutch drum screw was Rusty's effort to keep me from viewing the nuclear devastation that is his transmission! My lifetime of compiling bad karma effectively blocked Rusty's efforts. I spent about 8 hours milling away hardened steel in order to remove the clutch drum. I found a buggered triple gear pin, exploded triple gear bushing, broken triple gear tooth, a seized triple gear bushing, a broken brake drum bushing, a broken brake drum shaft and a stack of drums which do not want to come apart. On the plus side the weather is great and no way have I gotten anywhere near as much grief as I probably deserve!

Here is a photo of my brake drum shaft... can you see a problem?

- brake drum

- brake drum shaft

Just havin' fun in Penn Valley, CA! TH

OUCH!

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 9:22 pm

by Norman Kling

It appears to me that the last time the transmission was rebuilt, the bushings within the gears were too tight. They bound up and caused a disaster.

Norm

Re: Lost a tooth!

Posted: Mon Jan 18, 2021 10:31 pm

by Thorlick

Norman the Ford Service Manual calls for a running fit of .002” on triple gear bushings. If fit is .005” the bushing should be replaced. Following those instructions I reamed to .003” wanting to be sure to avoid seizing bushings. I used a piloted adjustable hand reamer.

So you don’t like .003” and Ford says .005” is too loose what is your specification? Exactly .004”? I need to know as I am about to repair my car.

Respectfully, TH

Re: Lost a tooth!

Posted: Tue Jan 19, 2021 1:11 am

by david_dewey

Terry,

As I understand it, "Running fit" means on each side of the shaft, so that would be .002 on each side, or measured the way we like to do it, .004 total difference. At least that's what I've been told!

Re: Lost a tooth!

Posted: Tue Jan 19, 2021 1:27 am

by Ken Buhler

Herman Kohnke and Jack Putnam are reputed to have been the two best builders of Model T engines in North America. You should look back to Hermans' post: Model T Transmission rebuild, The Way We Do It July 20,2013. 172 pages of "pay attention to detail and share with others"

Link

http://www.mtfca.com/discus/messages/33 ... 1375578307

Re: Lost a tooth!

Posted: Tue Jan 19, 2021 4:22 am

by dykker5502

Been there - done that. Maybe I should go and read Hermans post before I assemble my transmission.

It appears to be some locking wire that have broken off and entered the mesh and knocked a tooth off the center sunwheel.

(both wheel are samples from the scrappile - NOT from the actual gearbox!)

Re: Lost a tooth!

Posted: Wed Jan 20, 2021 11:08 am

by Thorlick

Norman,

I have received the suggestion that I set my triple gears at .005” from both Erik Barrett and John Kuehn. So I want to acknowledge your correct assessment.

I rely heavily on the Ford Service manual whilst working on my T. The fact that we have different lubricants and different bushing alloys as well as different oiling grooves obsoletes some of the published information. So with your insight I feel I can shoulder the blame for the demise of my late transmission. When I desire to shift some blame to the manuals I should now acknowledge I should have known better.

I couldn’t find the article by Herman Kohnke, can someone please provide a source for that?

TH

Link

http://www.mtfca.com/discus/messages/33 ... 1375578307

Re: Lost a tooth!

Posted: Wed Jan 20, 2021 1:30 pm

by Scott_Conger

There is no need to guess. The old term "running fit" has been defined in modern engineering terminology to include a multiple number of classes of fit for any number of environmental conditions. To be sure, a .002 running fit in 1909 did not

mean ".002 on each side of the bearing", although, in

practice, that is exactly what you may end up with depending on the class of fit you choose and the tolerances involved. The ".002" part of the running fit definition is the indication of the

Class of fit to apply to the "running" callout. This is not opinion. If you can find the early engineering manuals, and they are complete, you can begin to understand the mind of the early 20th Century enginner and begin to truely appreciate the marvels they created with the level of understanding of materials that they had. We frequently do not give them credit enough for their knowledge, much of which is generally lacking in today's graduate engineers. Specs like ANSI work well to fill the void of knowledge, by applying rote application of standards in the absence of understanding. The longer the graduate engineer plies his trade, usually the greater appreciation he gains for the Old Boys for what they accomplished.

With respect to the oft discussed and argued triple gear bushing, with modern specs, the class of fit would fall generally into RC7 and with that, experience has shown that the

high end of the fit clearance is desired. So, the thoughtful repairman can refer to a spec and then guided by wisdom and experience, chose the proper end/range of the allowed fit.

For those interested in the ANSI specs regarding this see the definition of RC7/8:

https://en.wikipedia.org/wiki/Engineeri ... nning_fits

And then use the engineering calculator to define what you want:

https://www.engineersedge.com/calculato ... rances.htm

Glen Chaffin and Herm Kohnke would go toe to toe on this with each giving their learned opinions. Glen was a proponent of the ".002 on each side camp". In reality, he was right, but for the wrong reason...right, because it worked, wrong because he as well as others simply made up mechanical engineering definitions which never heretofore existed. Herm swore somewhat closer fit was waranted, based on his "like new" Stevens(?) reamers gave a closer fit. He had great success where others have and often typically have total failure and disaster. In Herm's case of success and others swearing that Herm should not believe his lying eyes, there is a thing called "Workmanship".

Not all rebuilds are equal.

Re: Lost a tooth!

Posted: Sun Jan 24, 2021 11:35 pm

by David Fuls

By Herman Kohnke on Thursday, May 12, 2011 - 11:01 pm.

The Wilson reamers cut the Triple gears at exactly, .004 thousandths larger pin clearance. I have all the spec's, as we just got another Tranny done.

Re: Lost a tooth!

Posted: Mon Jan 25, 2021 12:35 am

by Allan

By the way of interest, Terry Thomas had not lost a tooth. There is simply a gap between his two front teeth.

Allan from down under.

Re: Lost a tooth!

Posted: Mon Jan 25, 2021 11:59 am

by Adam

That fractured driven gear shaft is something that occurs just about only on the wide drum of the ‘26-‘27 engines and is a result of slight alignment issues between the crank and fourth main, combined with the fact that the ‘26-‘27 powerplant assembly is much more rigid due to the top of the hogshead being bolted to the back of the block. In other words, it was caused by an alignment issue. HOWEVER, the alignment issue may not have been in that engine. It could have been at any point in that brake drum/driven gear sleeve’s past history. It is important to carefully check the driven gear sleeves of ‘26-‘27 large brake drums before re-use. Pay particular attention to the inside bore. Voids in the inside of the forging are not uncommon and are a particular weak point.

Re: Lost a tooth!

Posted: Mon Jan 25, 2021 2:50 pm

by ChrisB

Link to Hermann's rebuild post

http://www.mtfca.com/discus/messages/33 ... 1375578307

Also posted the link above in several places.

Chris