Page 1 of 1

Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 6:58 pm

by Mopar_man

So I think I asked this one time before but I never got a definitive answer. What did Ford use for rivets on 1926 /7 quadrants? The rivets I got from Lang's are bigger than the holes. Now I know that they come a bit bigger from the vendors because the old rivets can make the holes larger. On my 26 you can see that they are so small you can just barley stick a Cotter pin in.

Were the 26/7 rivets small?

Do I drill them out and use the rivets from the vendors?

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 7:28 pm

by TWrenn

On my former '20 I just cheated and used bolts. Filled in the slots on the heads, painted them, cut the excess threads off at the nuts underneath, can't see them anyway, no one was the wiser. Worked fine. Sometimes ya gotta do what ya gotta do!

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 7:44 pm

by RajoRacer

All the steering column quadrant rivets were the same diameter & length (you need to trim length prior to peening) other than the "early" T's using brass ones.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 8:53 pm

by Mopar_man

This steering column rivet holes are a lot smaller than the rivets. I have another 26 column and the holes are the same size. I hate to drill them out and put the wrong rivet in. I'd like to do it the way it was done back then.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 8:58 pm

by DanTreace

Ford part # 3510, Factory No. 5041, Steering Gear Quadrant Rivet, 5/32" x 1 1/4".

Price List of Parts, March 1, 1920 lists above size. Price List of Parts, Aug.1, 1926 lists the same part.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 9:20 pm

by OilyBill

In my opinion, the rivets on that quadrant were one of Henry's rare bad mistakes.

My standard procedure is to tap the holes for 8-32 screws, and then install either brass screws (for my 1914) or plated screws (for a 26/27 I am working on) On the 26.27, I wound up with 10-32 round head screws, nickel plated.

The 1925 service manual has instructions to install taper pins. These require a special reamer, and then either one or 2 drills to form the hole for the reamer to be used in. Once the hole is taper reamed, the taper pins are driven in from the top.

The taper pins are better than the rivets, at least, because it is possible to tap them back out from the bottom side if you need to disassemble the quadrant again.

I have a complete set of taper pin reamers, but they are not that common, and would require a special purchase.

My advice is to stick with the screws.

EVERY PART OF THE CAR WILL HAVE TO COME APART AGAIN, EVENTUALLY.

Why make it harder on the future owner than it has to be?

With screws, the quadrant can be disassembled, and repaired or serviced, with ease. And it limits future damage to the steering column as well.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 10:17 pm

by varmint

Our '26 steering column is still disassembled. In the future, I might broach the hole and use small carriage bolts. Not sure yet.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 10:25 pm

by Mark Gregush

I've not had a problem with the standard size rivets, are you sure you didn't get the OS ones? Both sizes are listed in the catalog.

RE using screws, like, but how do you deal with the angle? The taper of the column housing would leave a gap under the screw head.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 10:30 pm

by Allan

Vernon, carriage bolts are not the answer. They have a rolled thread which is of a larger diameter than the shank of the bolt. A hole drilled to accommodate the thread will leave the gearcase loose on the bolt shaft.

Allan from down under.

Re: Steering Column Rivets for 1926/7

Posted: Tue Feb 23, 2021 10:49 pm

by varmint

- carriage bolt.jpg (4.47 KiB) Viewed 5331 times

This is what I had in mind. Round head, square neck and full thread, no shank.

Broaching the surface but not the entire shaft. Now I'm curious to see what a carriage bolt looks like from down under.

Of course the head would need some grinding.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 12:13 am

by jiminbartow

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 12:51 am

by Allan

Vern, a coach bolt has a round head with square shank under it, just like your photo. Then they usually have just an inch or so of thread at the end of the bolt shaft As they come in 1/2" increments of length, there is no need for longer thread. That rolled thread is the nominal size, but the shaft of the bolt is thinner. Your photo shows an all thread bolt. Perhaps these are made to eliminate the need for the 1/2" increments of length, and thus less inventory for the stores to carry. It is still not a good solution for a steering column. The brass gearcase can only engage on the tips of the thread and will soon wear loose. Every time you turn the wheel, the case will be loaded onto those threads and it will very soon look like the inside of an A model front wheel bearing that has been fitted to a T model threaded spindle, only worse, because the brass will wear much more quickly.

Allan from down under.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 1:30 am

by Ken Buhler

It is important to look back on posts on this subject. The steering column is secured at it's base. The quadrant MUST be riveted properly so that the tube does not twist. If it does, you will get inaccurate and mushy steering. Very dangerous.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 6:11 am

by varmint

Looks like the correct part is 3509RST from the vendors.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 9:30 am

by TWrenn

Ken, as William Mav (Oily Bill) above mentioned, the screws/bolts I used, round headed, and as I said I filled in the slots, did the trick. No mush steering. AND, had I kept the car and needed to, I could've taken it apart again a whole lot easier. Just my thoughts.

This guy needs to do what makes him sleep better at night.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 11:11 am

by jiminbartow

Since on many older T’s the quadrant is brass, or newer T’s like my ‘26 coupe, the quadrant is nickel plated and cannot be painted to conceal the putty used to convert a slotted screw to a round headed rivet, an as close to correct, shiny metal solid rivet, such as stainless steel should be used which when buffed to a bright, mirror like shine, matches the nickel plated quadrant and stainless steel holes that shine without a protective coating of lacquer. If all you can find is steel, steel can be polished and buffed to a mirror finish and coated with lacquer to keep it that way. Aluminum rivets are too white. Jim Patrick

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 11:20 am

by jiminbartow

I just had a thought. Has anyone ever considered buying round headed rivets and threading them so as to use Tim’s idea to make it so it can be dismantled in the future while maintaining the original riveted look, at least on the top. Of course there would be the problem of sufficiently tightening the nut with nothing to hold on to to keep the threaded rivet from spinning. Jim Patrick

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 12:53 pm

by Mopar_man

Thank you all for your help and input. I bought a set of rivets 3509RST from Lang's. I want to rivet everything back as original. I know that the rivets are made a bit oversize because the holes are usually worn and larger than original. But i go back to my original question: Why are the holes so small? If the answer is they came that way and the new rivets are oversized to compensate for a worn out hole and rivet I'm ok with that and I will drill out the tube and quadrant for the 3509RST rivet.

I also went and placed a 5/32 drill bit in the hole. That's to correct size. The rivet just looks too big But then again that could be to compensate for a larger hole.

Thanks again everyone.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 1:30 pm

by RajoRacer

Threaded rivets are available through Restoration Supply Co. in California.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 1:35 pm

by DanTreace

Robert

Have used many of these rivets from Lang’s. They are all 5/32” like original. Catalog states .155” and mine on hand mike the same, including the original with its now flatted and angled head from rivet set.

Passes snug into original quadrant holes. Mike the rivets you got, they may be off, should be .155”

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 3:16 pm

by Mopar_man

I'm going to order another set. Cheep insurance against disaster.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 3:52 pm

by TWrenn

Jim, that's a good idea. Sure beats heating them cherry red, then squeezing or pounding the crap out of them, then hoping to you know who they still draw up tight. As I recall, once there was tension on my bolt, I didn't even need to hold it with a screwdriver. I'd bet it wouldn't be hard to hold a round head rivet in place, and it shouldn't be hard to thread the end of it.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 4:17 pm

by jiminbartow

Yes. Only the last 1/2” would need to be threaded and if you needed something to hold onto, you could cut a slot into the threaded end with a dremel tool to hold with a standard screwdriver, or flatten the threaded end on opposing sides with a dremel tool with which to hold with a small wrench. This would also allow you to nickel plate the rivet head with an electro-plating pen. Jim Patrick

- A9B00D47-61EB-4EC9-AC99-28B32EEBA121.jpeg (23.01 KiB) Viewed 5153 times

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 4:32 pm

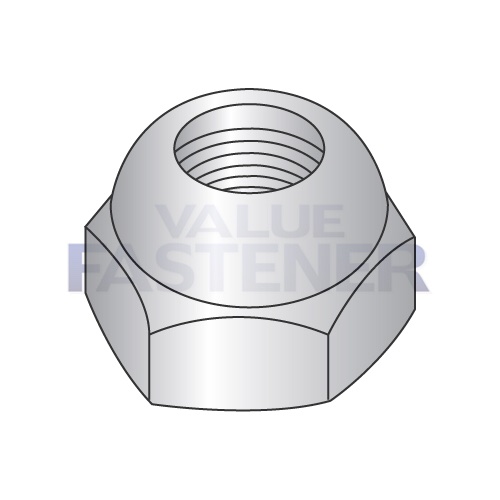

by Allan

What kind of nut is suggested for use on the end of the bolts/threaded rivet? Any nut will have flats, and as they are tightened, they will tend to snag on the points a relax a smidgeon when the flat is parallel with the column. That is the nature of the beast when the bolt emerges from the hole at an angle as it does on the steering column. Does it require a wedge shaped washer under the nut? Perhaps making a nut with a taper on the back would do. Either way, it would not pass muster with the purists.

Allan from down under.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 7:25 pm

by jiminbartow

Allan. I would suggest an “open end cap nut”. Basically an open ended acorn nut that, when the dome end is positioned against the surface, will conform to angled or irregular surfaces. Jim Patrick

- D4C780BE-D8C7-402A-8A72-428B91F51E7C.jpeg (37.93 KiB) Viewed 5123 times

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 9:09 pm

by Allan

That'd do the trick Jim, but not that particular one. The draftsman forgot to run the thread right through!!!!!

Allan from down under.

Re: Steering Column Rivets for 1926/7

Posted: Wed Feb 24, 2021 9:39 pm

by DanTreace

Just too Henry I am. Rivets are best at the quadrant.

Threaded screws or bolts, nuts, lock washers, can wiggle loose within the holes of the soft brass case, and all will protrude and would snag my hand, at times reaching under the quadrant. Smooth rivet head there is better.

My use is a pneumatic rivet gun, setting the rivets cold, bucked tight under the column and quadrant. Rivets placed into the softer brass steering case lock in better, due to the angle these rivets are placed. Fix is secure at this very important part, the steering gears are under the steering wheel. Make this assembly the best you can.

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 11:01 am

by Original Smith

I'm working on a 1914 currently. I haven't gotten to the rivets yet but will. Be sure to save the originals and reshape the heads to conform to those. There is nothing worse looking, in my opinion, than the incorrect shape rivet heads on a quadrant.

A question I've been wondering about for a long time, do you think Ford had a fixture for drilling those holes? When I did my '25 I had to transfer the holes from the tube to the NOS quadrant I wanted to use. It was very time consuming.

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 11:20 am

by varmint

Larry,

I would guess that if a fixture saved time it was done. Of course there could be more than one fixture and it would not matter except to someone years later kinda like trying to match '26 coupe body parts from different coupes.

All,

What if the shank end of the 3509RST rivet was annealed, split or cut, inserted through the steering assembly, folded over, and then a weld bead was applied to the end and cleaned up.

Opinions?

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 11:43 am

by DanTreace

Vern

Guess one could do anything to the T steering column. But any wiggle at the quadrant/steering case needs to be fixed.

IMO, remove the old rivets, inspect the column for any crack, then replace the re-finished case using factory method of riveting.

Of course, welding is one way

- welded up loose quadrant.jpg (59.04 KiB) Viewed 5016 times

IMO, easy to re-rivet, and gives the best look and security, as in the one I did below:

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 11:44 am

by RajoRacer

Vern - I understand the purpose to peen the rivet is to tightly swell the rivet into the space it occupies.

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 5:18 pm

by John Codman

I used Lang's rivets on my '27 and they fit perfectly. Are you sure that your column is a '27?

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 5:21 pm

by RajoRacer

Same sized rivets, John !

Re: Steering Column Rivets for 1926/7

Posted: Thu Feb 25, 2021 6:34 pm

by Allan

Re Larry's "fixture" to hold the column while drilling/riveting, there would have to be some kind of backing to do the riveting. The problem for us is the drilling. I have never found I could interchange the column tube/quadrant /gearcase, without having to re-drill components to align the holes. This would indicate that each column is assembled as an individual unit. Rebuilding a column using all its original components should not cause so much grief, but substituting parts from another will. To make this possible, I drill and tap the gearcase holes and screw brass all-thread to fill the holes. Then I weld shut the 4 holes in the tube and the two lower holes in the quadrant. That way the quadrant top holes provide a guide to start the drill, and the drill cuts a new, aligned hole through the rest. It is still best to have an extra et of eyes to help align the drill at the start.

Hope this helps someone.

Allan from down under.