Page 1 of 1

How do I use this tool?

Posted: Thu Jun 10, 2021 10:14 am

by It's Bill

A couple of years ago, I rebuilt my Ruxtell rear axle using new hubs, axles, and keys from Langs. These parts were made to perfection, but fit together so well that now I cannot get the rear wheels off. I tried the screw-on puller in the photo, but it had no effect other than starting to damage the axle threads. No real harm done, but no joy either.

So I bought the “knock off wheel puller” in the other pix, but I am not sure how to use it. I recall reading something about jacking up the wheel you do NOT want to remove, leaving the wheel you want to remove on the ground, removing the axle nut, installing the knock off in its place, and then giving it a good whack with a large hammer.

It seems to me that you are in essence keeping the wheel and hub stationary and moving the rest of the car away from it via hammering on the axle. The last thing I want to do is bugger up my nice fresh rebuild. So my questions are: Is this how this tool is used? If it is, how hard do you whack it? How many times should you whack it before you stop? What components in the rear end take the force of the whack, and can they be damaged? I’m thinking thrust washers, gears, Ruxstell parts? And if I am mistaken about all this, can someone please give me clear step by step directions on how to use these tools?

Stuck in Paradise, Bill

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:21 am

by Erik Johnson

RE: knock off

Jack up the opposite wheel.

Keep the wheel you want to remove on the ground.

Hit the knock-off with a large hammer.

This is how it works: the wheel that you want to remove remains stationary while the car/axle moves slightly when you hit the knock-off.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:22 am

by TWrenn

Generally I only have to thread on the puller...tighten the small bolt, tighten the long larger bolt on the end, gove it a rap or two with a hammer...then co ti ue tightening the bolt on the end til the wheel breaks free. Be sure to release the parking brake!

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:26 am

by Dropacent

ALWAYS thread the small knockoff nut fully onto the axle threads, until it bottoms out.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:29 am

by Jim Sims

You are correct on using the knock off puller. With the wheel you wish to pull set on the ground, You are knocking the rest of the T out of the wheel. The force is stopped at the wheel and not transfered inside the differential. Tighten the puller as tight as possible and hit it with a heavy hammer about two times. Then re tighten the puller and hit again. KEEP THE PULLER TIGHT !!!

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:32 am

by speedytinc

Dont use the knock off tool. Easy to damage that axle stub. For tough fits, ese the screw on puller(1st pix).

Loosen the nut one revolution. Put the puller on & tighten the square head bolt. Real tight. Drive the car, a few right & left turns. Should release.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 10:44 am

by DanTreace

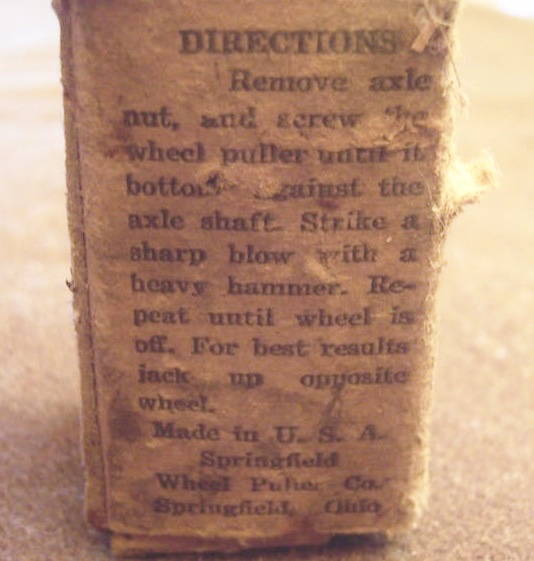

Knock Off, used correctly won't harm the axle threaded end. Only if the Knock Off is bad or you don't thread it til it bottoms out on the axle end. The Knock Off threads are deep.

- Wheel puller instructions - Copy.jpg (120.27 KiB) Viewed 4340 times

Or if you have the hub thread 'puller' tool, that works similar. Thread on the tool fully, then seat the bolt end against the axle shaft. Tighten fully with large wrench. Then whack on the large bolt head to 'shock' the axle back some from the wheel hub taper. Sometimes tightening again the tool or the bolt for stubborn axle to hub interface.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 11:15 am

by Original Smith

The best one was made by Ford in later years, and has a built in knocker, and a Ford script.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 1:12 pm

by Scott_Conger

The key issue is "I bought a new hub..."

And not just any hub...you bought a new steel hub

The original hub was not steel and while it can be tough, is not as reluctant to release as steel is

Loosening the axle nut, reversing it and threading it on backwards such that it protects the threads of the axle, then putting on the wheel puller TIGHTLY, and going for a short drive may be the only way in the world to get those two particular parts apart.

I think this is going to be a more common thread in the future as these hubs become serviced. I've seen several that were fiercely seized and when released showed a very small amount of fretting. I'm thinking that even as new, this combination may be best assembled with a thin SS shim simply for removal purposes.

No, greasing the axle before assembly is not the answer unless the question is: "How can I really wreck things?"

Good luck, because I know all too well just how stuck that thing really is.

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 1:35 pm

by It's Bill

Thanks to all. Boy, it would be great if the vendors would simply include a stainless shim with each hub. Scott, it never occurred to me that steel on steel would cause this issue. Now I am filled with trepidation and dread. I did put an extremely thin wipe of old fashioned lead based anti-seize on the parts before assembly. I will post the outcome if I can still read and write when the task is done.

Another fine mess, Bill

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 1:46 pm

by speedytinc

The issue with the shims, is that they flake apart & move toward the outer seal. Seal gets cut up & leaks. No good. How you going to prevent that??

Did/would the anti-seize hurt or help this issue? There must be a good answer. Another problem repo part? Is the definitive answer an original hub with longer axles?

Re: How do I use this tool?

Posted: Thu Jun 10, 2021 3:11 pm

by Scott_Conger

Shims will stay put if some time is taken to mate the worn parts or at a very minimum rework offending spots which keep parts from seating. They will only squirm if there is relative movement between the two parts and I would doubt that would be the case with a new axle and a new steel hub. This assumes one is not using barrel shaped axles with barrel shaped hubs. There comes a point where two parts cannot be safely assembled and if doing so anyway causes shims to be destroyed, well...

As for movement? Yes, I've seen it and it will do exactly what you stated. Did it to me on my very first installation on my first T. Fixed that by solving the root cause. Since then, I run them on my cars, many thousands of miles, as well as cars I have worked on for others. I have never received a complaint for shims moving or degrading on work which I have performed. If a complaint arises I will deal with it, as there is always a first time.

Re: How do I use this tool?

Posted: Sun Jun 13, 2021 1:51 pm

by Chris Haynes

Use Anti Seize???

Re: How do I use this tool?

Posted: Sun Jun 13, 2021 3:23 pm

by Norman Kling

Would it work to put a bit of graphite on the axle before installing the hub?

Norm

Re: How do I use this tool?

Posted: Wed Jun 16, 2021 6:52 pm

by John_Aldrich

I once had a wheel I could not get off with either of the tools shown.

I ended up backing off the nut a couple of turns (so it was loose but not falling off) and then driving the car a little making tight turns both left and right.

That worked when nothing else would.