Page 1 of 1

How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 3:23 pm

by Dan Hatch

Guys: Looking for input. Got a block here that someone else has put modern valves in. Couple guides were bored off square with sear. Stick valve in and it is off center of tapper. Put pilot and not square with top of block. How to fix.

Thinking about bore with core drill, ream and drive in guide. But will that square it up? How have any of you fixed this problem?

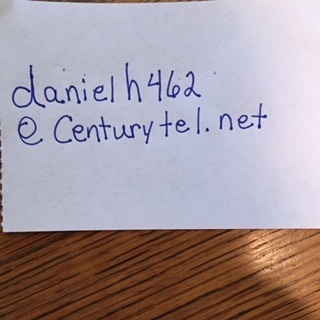

Here is my email if you need it. Thanks Dan

- 2B457A98-D06B-4FCE-9E8D-B94B6F62619A.jpeg (34.02 KiB) Viewed 2298 times

Re: How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 4:01 pm

by Philip

it depends on how bad it is. if off just a little a good piloted valve seat cutter will work.

if it is way off it will need new seats

Re: How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 4:03 pm

by Henry K. Lee

Dan squaring up on a milling machine should do it on a slow plunge. It is in the car? If so maybe make up a guide and use a jobber long mill end.

Just an Idea,

Hank

Re: How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 4:13 pm

by Scott_Conger

I think Henry pretty much nailed it

As an ugly option to doing it right I will admit to doing the following once for a friend under his carport in blazing FL heat and humidity: Someone "reamed" with a hand drill and while the valves were new, they were not centered (though had a surprisingly good fit in the guide). The valves were at the largest size so there was no correcting the guides under the circumstances I was working.

As the valves were slightly canted and not centered over the seats, I sent the valves out to be kissed on the faces to ensure concentricity and I simply cut new seats in the block with a neway cutter and was done with it. Car ran great. Car was an eBay purchase and barely ran when he received it.

Now for the rest of the story...I am now the recipient of that shade tree job. Years later, my friend died, the car was sold to a guy in TN who cut off the pan ears, dropped the engine on the ground and promptly put an industrial engine in the car. Not knowing the butchery done on the engine, I agreed to buy it sight-unseen and it is sitting in my dad's garage in TN. So, hate me if you will for doing that kind of job, but the fates determined that I would live with those valves but not all of the pan.

Re: How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 5:07 pm

by Dan Hatch

Mounted on mill now. Had to order tooling. That is way I was thinking. Thanks guys.

Re: How to square a valve guide hole to seat?

Posted: Mon Jul 19, 2021 8:19 pm

by Allan

My local machine shop mounts the block in a mill, and bores the old guide out to fit a replacement small block Chev guide.

Allan from down under.

Re: How to square a valve guide hole to seat?

Posted: Wed Jul 21, 2021 10:35 am

by BobShirleyAtlantaTx

I would suggest using an flat face end mill in a milling machine to bore the guide hole, centering it from the valve seat. That way it will be less likely to follow the old hole. Once bored, ream to fit the new guide, press in a new guide a ream for valve clearance. Cut the valve seat to the guide hole. If I can help 903-824-1949