Page 1 of 1

Axle key way fit

Posted: Sun Aug 15, 2021 8:02 am

by John L

Just got everything remounted back on the 23 . I tried to fit the key way on to the new axles, but the slot where the key way fits is to tight. Is is common that you have to fit the key way to the new axle ? They fit perfectly into the wheel hub.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 8:37 am

by Kerry

The key is 1/4" x 1/4" if it dose not fit in the axle then they are made incorrect or the keys and hub slot has been made over sized to repair some time in it's life.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 11:01 am

by John L

The keys that I bought from the suppler fit the hub but not the new axle.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 11:02 am

by DanTreace

Found the same with new axles, mfg. by Snyder's, and are very nicely made, correct to Ford print. Placed a pair recently in the '25 coupe project, and used the Ford manual way for fitting the key.

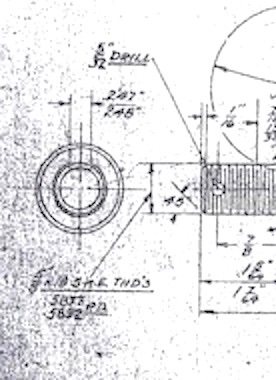

New axles are just on Ford print, that is the keyway for the hub key on mine was .2475". Right at the tolerance of .247-.248. That is the Ford dimension.

- Ford rear axle print.jpg (43.78 KiB) Viewed 3945 times

New keys come in about .249". That is the way of the key.  Follow the Service Manual on install, Chapter XIV, paragraph 639, ".....inserted into keyway on axle as shown at 'B' {key, taper end down, and toward axle housing} and is forced into the keyway by tapping it with a small hammer." I use a brass hammer to do this job.

Follow the Service Manual on install, Chapter XIV, paragraph 639, ".....inserted into keyway on axle as shown at 'B' {key, taper end down, and toward axle housing} and is forced into the keyway by tapping it with a small hammer." I use a brass hammer to do this job.

The key must be tight in the axle shaft or rocking will occur, causing a loose hub, or worse, a busted axle keyway !

Re: Axle key way fit

Posted: Sun Aug 15, 2021 11:57 am

by henryford2

I've spent the majority of my working carer around special machine building & tool & die making. Very seldom have I even seen a machinist or tool & die maker take "standard sized" 1018-1045 carbon steel machine key stock and fit it to a keyway without stoning or worse case surface grinding it to fit. A "standard" 1/4" x 1/4" key stock should measure .249- .251, oversized .250 - .252 and undersize .248 - .250. The Ford print indicates a .247 - .248 keyway width. So even using undersized key stock there is still a chance you'll need to fit it or "forced in by hammering". Just my humble opinion. Enjoy

Re: Axle key way fit

Posted: Sun Aug 15, 2021 12:04 pm

by RajoRacer

This has been an issue on new axles for some time now - I brought up the subject and was notified by Snyder's that the new axles are indeed machined to Ford specifications BUT stock, dimensional 1/4" keys won't GO ! I purchased lengths of "undersize" 1/4" key stock from McMaster-Carr and fit my own to each axle - P.I.T.A. but that's the way it is !

Re: Axle key way fit

Posted: Sun Aug 15, 2021 12:17 pm

by speedytinc

This sounds like a GOOD problem. One could always file a bit off the edges that fit the axle slot.

Its GREAT to hear a reproduction part is made to FORD specs. Too many are not.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 12:26 pm

by Dropacent

I would agree with all of the above EXCEPT you need to be careful fitting the keyway properly to the axle and then having a key too sloppy in a 100+ year old hub. Also, there are good original axles out there with the keyway a bit wide. As Joe says, hand fitting it to each can give you a stepped key, which is perfectly fine. Each install will be different and requires simple craftsmanship. I’ve found running a fine file along just half of the key at a time is the simplest and easiest method. NEVER just pound a unknown key into an unknown axle !! JMHO !

Re: Axle key way fit

Posted: Sun Aug 15, 2021 12:34 pm

by speedytinc

Dropacent wrote: ↑Sun Aug 15, 2021 12:26 pm

I would agree with all of the above EXCEPT you need to be careful fitting the keyway properly to the axle and then having a key too sloppy in a 100+ year old hub. Also, there are good original axles out there with the keyway a bit wide. As Joe says, hand fitting it to each can give you a stepped key, which is perfectly fine. Each install will be different and requires simple craftsmanship. I’ve found running a fine file along just half of the key at a time is the simplest and easiest method. NEVER just pound a unknown key into an unknown axle !! JMHO !

Good point. Measure & for fit before using the hammer.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 4:47 pm

by Scott_Conger

I'd love to see the drawing of a hub and from that gather exactly what the tolerance and fit of a standard(?) key was at the factory.

Keys in industry come in a myriad of styles for a "1/4" key...undersize, oversize, stepped, etc. I doubt that much thought is given to where the keys come from that are turned into keys for "T"s. If it was a Fun Projects part or an RV Anderson part, I'd believe some thought went into it, but doubt very much if anyone else has or will.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 5:42 pm

by John kuehn

The keys are probably made from stock 1/4” key stock bought from where ever. Snyder’s axles are well made. The one I bought years back was correct and looked pretty good. I do remember that I had to fit the key to the axle and hub. It a tight fit that Involved using a file. I did use a brass drift with my hammer to get it in. To me it has to be pretty tight. But looking back I do remember thinking that the key was a little to big.

I was a maintenance mechanic working at a small college and fitting keys to new motor pulley s and exhaust fans was an issue sometimes and fitting the key to the key way was something you did pretty often with new pulleys on large industrial motors and large fan blades. It just goes with the job.

Re: Axle key way fit

Posted: Sun Aug 15, 2021 7:47 pm

by henryford2

another small practice was to lightly stone the sharp corners of the key. Reasoning being that if the edge of the cutters used to machine the slot would breakdown they would leave a very slight radius in the corners of the keyway (not necessarily a bad thing, I've seen my share of broken key ways on Model T axle shafts from the "sharp" corners). The radius in the corners of the keyway would prevent the key from sitting all the way to the bottom of the keyway if its' edges (corners) were left sharp. Enjoy, Joe

Re: Axle key way fit

Posted: Sat Aug 21, 2021 4:29 am

by D Stroud

In a past life, I worked as a maintenance supervisor in a Lead Recycling plant. All of the "generic" keystock that we got was made one or two thousands over sized to be fitted for the application. We just touched them up on the side of a pedestal grinder wheel to fit. That being said, they weren't being used for both forward and reverse applications such as a T axle, but worked fine for our use. Dave

Re: Axle key way fit

Posted: Sat Aug 21, 2021 12:34 pm

by greenacres36

I’ve been a machinist and to die maker for over 30 years. Any time that I’ve ever made a key from scratch it was supposed to be .001 or so oversize. That is so the mechanics in the field could fit the key to the keyway. Most often the keyway is around .001 under what we would call a normal size. Doesn’t matter if it’s inch or metric. It’s actually a good thing because I would want that key really tight in the axle. One of the few nice things about metric is in my experience the keyway was deeper. Meaning the axle keyway would support the key better from rolling. But thankfully Henry didn’t use too many metrics. LOL I guess except for a few spark plug heads for overseas.