A Crank in T. Practice

Forum rules

If you need help logging in, or have question about how something works, use the Support forum located here Support Forum

Complete set of Forum Rules Forum Rules

If you need help logging in, or have question about how something works, use the Support forum located here Support Forum

Complete set of Forum Rules Forum Rules

-

got10carz

Topic author - Posts: 497

- Joined: Sun Jan 06, 2019 6:37 pm

- First Name: Steve

- Last Name: Meixner

- * REQUIRED* Type and Year of Model Ts owned: 1911,13,14,19,23,25,26,27

- Location: Moorhead MN

- MTFCA Number: 28023

- MTFCI Number: 20471

A Crank in T. Practice

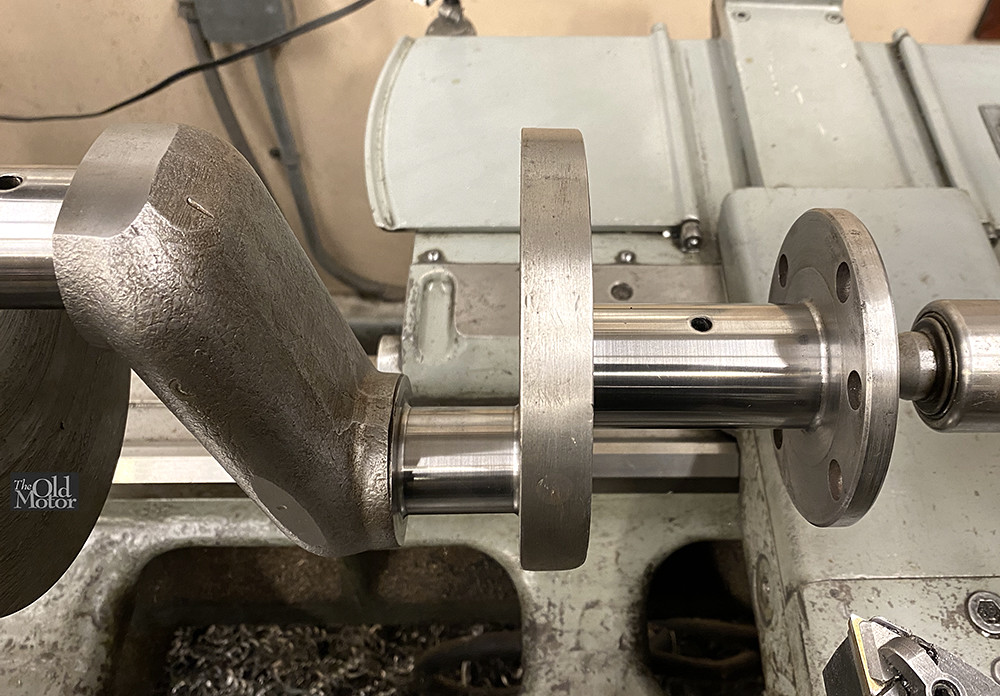

Practicing on junk block, and looking for constructive criticism. Do these numbers make sense to those of you that have done this.This is the amount I removed from the side of each main saddle.

-

Erik Barrett

- Posts: 463

- Joined: Mon Jan 07, 2019 12:32 am

- First Name: Erik

- Last Name: Barrett

- * REQUIRED* Type and Year of Model Ts owned: 1913 speedster 1924 touring 1925 dump truck

- Location: Auburn, Ca.

Re: A Crank in T. Practice

I can’t see your numbers in the pic, but when I do these I bore the block out to the edge of the main bolt holes for babbit bearings. For insert bearings you have to use the housing bore dimension required by the bearings used.

-

Kevin Pharis

- Posts: 1360

- Joined: Thu Jan 10, 2019 3:54 pm

- First Name: Kevin

- Last Name: Pharis

- Location: Sacramento CA

Re: A Crank in T. Practice

Erik is speaking to the next step in the process... boring out the bearing bores

Your numbers seem ok to me. I don’t recall the center main bearing moving, but the inner halves of the front and rear do get cut. Pay attention to the timing gear position, and all else should fall into place

Your numbers seem ok to me. I don’t recall the center main bearing moving, but the inner halves of the front and rear do get cut. Pay attention to the timing gear position, and all else should fall into place

-

Henry K. Lee

- Posts: 5339

- Joined: Sun Jan 06, 2019 11:09 am

- First Name: Henry

- Last Name: Lee

- * REQUIRED* Type and Year of Model Ts owned: Many

- Location: South Pittsburg, TN

- MTFCA Number: 479

- MTFCA Life Member: YES

Re: A Crank in T. Practice

As stated above.., you are on it!

Hank

Hank

-

got10carz

Topic author - Posts: 497

- Joined: Sun Jan 06, 2019 6:37 pm

- First Name: Steve

- Last Name: Meixner

- * REQUIRED* Type and Year of Model Ts owned: 1911,13,14,19,23,25,26,27

- Location: Moorhead MN

- MTFCA Number: 28023

- MTFCI Number: 20471

Re: A Crank in T. Practice

I made the .010 cut on center main thinking it would give you some fudge up room when the thrust is cut on rear cap.

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

Just wondering how you plan to “manage” the extra crank length.

I’ve used various methods (all successfully)!

Shorten by welding

Shorten without welding

Shift the block ahead

I’ve used various methods (all successfully)!

Shorten by welding

Shorten without welding

Shift the block ahead

-

got10carz

Topic author - Posts: 497

- Joined: Sun Jan 06, 2019 6:37 pm

- First Name: Steve

- Last Name: Meixner

- * REQUIRED* Type and Year of Model Ts owned: 1911,13,14,19,23,25,26,27

- Location: Moorhead MN

- MTFCA Number: 28023

- MTFCI Number: 20471

Re: A Crank in T. Practice

Les, I plan to shorten a counterbalanced B by welding. I also collected several sets of Model A X rods and will use them. I see you've done this, you may be my new best friend. Also plan on using B cam.

-

speedytinc

- Posts: 3866

- Joined: Fri Feb 12, 2021 12:24 pm

- First Name: john

- Last Name: karvaly

- * REQUIRED* Type and Year of Model Ts owned: 14/15 wide track roadster. 23 touring, 27 roadster pickup, 20ish rajo touring

- Location: orange, ca

- MTFCA Number: 14383

- Board Member Since: 2020

Re: A Crank in T. Practice

FWIW, I heard threading, then welding.

I believe Dan M. used this method on a C crank for me. Heard of weld only cranks failing.

Went to an expert for the best job done once.

I believe Dan M. used this method on a C crank for me. Heard of weld only cranks failing.

Went to an expert for the best job done once.

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

The trick for a successful welding version is to ensure that you have a FULL penetration weld done by a competent welder. I Ved one side and preheated. Then put it back in the lathe and Ved the other side back to the welding. Now preheated again and finished the welding. Wrapped it to allow to cool slowly. Then finished the machining. I did this 40 years ago and this engine is still running STRONG (4200 rpm and 100 mph)

I have now done several using a NO welding method. I will post some pictures tomorrow.

I am in process of doing one with a cutdown to stock A size crank identical to yours. On it I have shifted the block 5/8” forwards. I have extended the camshaft and am using a flathead V8 oil pump

I am in process of doing one with a cutdown to stock A size crank identical to yours. On it I have shifted the block 5/8” forwards. I have extended the camshaft and am using a flathead V8 oil pump

-

Dan McEachern

- Posts: 1188

- Joined: Sun Jan 06, 2019 11:08 am

- First Name: DAN

- Last Name: MCEACHERN

- * REQUIRED* Type and Year of Model Ts owned: too many. '14 touring, 2 depot hacks, 2 speedsters

- Location: ALAMEDA,CA,USA

Re: A Crank in T. Practice

John- I don't want to even think about how many years ago I did that crank for you!!! Anyway, its not threaded, just a proper weld job with full penetration from both sides. Over the years, I've seen squares, threads, T crank rear mains pressed inside, the full gamut, bottom line is they all fall off eventually due to a poor weld.

Steve- I have a shortened counterweighted B crank sitting here if you are interested. A main size, B rod size. A very old customer job that was never picked up. Contact me if you are interested.

On the block, no need to narrow the center main saddle.

Steve- I have a shortened counterweighted B crank sitting here if you are interested. A main size, B rod size. A very old customer job that was never picked up. Contact me if you are interested.

On the block, no need to narrow the center main saddle.

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

My “No Welding” method. This has been successfully used. The new flywheel hub is made of 4140

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

A shot of the front end modification. I have installed a “Speedi Sleeve” for the seal/packing to run on

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

“C crank (no Speedi Sleeve yet)

Un modified back end

Shortened pan front end

STRETCHED pan!

-

speedytinc

- Posts: 3866

- Joined: Fri Feb 12, 2021 12:24 pm

- First Name: john

- Last Name: karvaly

- * REQUIRED* Type and Year of Model Ts owned: 14/15 wide track roadster. 23 touring, 27 roadster pickup, 20ish rajo touring

- Location: orange, ca

- MTFCA Number: 14383

- Board Member Since: 2020

Re: A Crank in T. Practice

I stand corrected on your method. For some reason my memory isnt improving with age.

I do stand uncorrected for taking it to the right professional for the conversion. Thanks again.

I do stand uncorrected for taking it to the right professional for the conversion. Thanks again.

-

speedytinc

- Posts: 3866

- Joined: Fri Feb 12, 2021 12:24 pm

- First Name: john

- Last Name: karvaly

- * REQUIRED* Type and Year of Model Ts owned: 14/15 wide track roadster. 23 touring, 27 roadster pickup, 20ish rajo touring

- Location: orange, ca

- MTFCA Number: 14383

- Board Member Since: 2020

Re: A Crank in T. Practice

I see 2 set screws. There must be more magic involved. More than a press fit?Les Schubert wrote: ↑Fri Oct 29, 2021 6:04 pmimage.jpgimage.jpg

My “No Welding” method. This has been successfully used. The new flywheel hub is made of 4140

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

John

It is a tapered shrink press fit. The set screws are just for a added safety factor.

The hub is heated to 500 F and pressed on. When cool it is machined all over

It is a tapered shrink press fit. The set screws are just for a added safety factor.

The hub is heated to 500 F and pressed on. When cool it is machined all over

-

got10carz

Topic author - Posts: 497

- Joined: Sun Jan 06, 2019 6:37 pm

- First Name: Steve

- Last Name: Meixner

- * REQUIRED* Type and Year of Model Ts owned: 1911,13,14,19,23,25,26,27

- Location: Moorhead MN

- MTFCA Number: 28023

- MTFCI Number: 20471

Re: A Crank in T. Practice

Today I thought I would take a old A cam and machine the journals to size. Was I ever surprised to find that the journals are case hardened, machineable but slow. I think when it comes to a finished product I will machine to .010 and have a crankshaft grinder finish to size.

-

Les Schubert

- Posts: 1319

- Joined: Thu Jan 10, 2019 5:47 pm

- First Name: Les

- Last Name: Schubert

- * REQUIRED* Type and Year of Model Ts owned: 27 roadster 13 touring

- Location: Calgary

Re: A Crank in T. Practice

Consider installing the cam using the same “philosophy” as in the A (running directly on the casting without removable bearings). You will have to do some “creative work” to install the gear and run the ignition anyway, so “managing” the end float won’t be that difficult!

-

Erik Barrett

- Posts: 463

- Joined: Mon Jan 07, 2019 12:32 am

- First Name: Erik

- Last Name: Barrett

- * REQUIRED* Type and Year of Model Ts owned: 1913 speedster 1924 touring 1925 dump truck

- Location: Auburn, Ca.

Re: A Crank in T. Practice

To use a B crank in a model T engine you have to turn both the rod and main journals down to model A size, so you may just as well get a counterbalanced A or Scat crank. You can use B rods in a model T if you have an overhead cam engine with no cam in the block.

-

David Greenlees

- Posts: 168

- Joined: Wed Feb 02, 2022 1:18 pm

- First Name: David

- Last Name: Greenlees

- * REQUIRED* Type and Year of Model Ts owned: 1913 Model T racing car, 1924 Model T Depot Hack with original York #803 body.

- Location: Guilford, VT

- Contact:

Re: A Crank in T. Practice

This is a forged 1933 to '40 Model C Ford factory-designed and manufactured one piece counterbalanced crankshaft (NOT welded counterbalances.) I shortened it to fit a Model T and drilled for full-pressure oiling and T camshaft clearance. All oiling holes drilled on an angle in one shot (not for the faint of heart) except for the rear rod journal that is crossed drilled (to get the oil feed hole in the center of the rear main.)

The OD of the crankshaft machined for camshaft clearance.

It was magnafluxed before and X-rayed after the conversion. The flange welding one side at a time (shortened rear main) was done by expert certified welders at Mercury Welding using the correct welding rod for the alloy Ford used to forge it from and used the right preheat and cool down procedures. https://mercurycorp.com/home-3/capabilities/welding/ when they were in the nuclear power plant welding business and had a shop near a nuclear power plant here in VT. They welded several of them for me and none of them ever cracked or broke after being driven 1000's of miles.

-

David Greenlees

- Posts: 168

- Joined: Wed Feb 02, 2022 1:18 pm

- First Name: David

- Last Name: Greenlees

- * REQUIRED* Type and Year of Model Ts owned: 1913 Model T racing car, 1924 Model T Depot Hack with original York #803 body.

- Location: Guilford, VT

- Contact:

Re: A Crank in T. Practice

got10carz: Your crankshaft looks really nice, did you modify it yourself or did a shop do it for you? Is the rear main shortened or was the block moved forward? How did it work out for you in the end? Did you install the B camshaft on the right side of the photos as well?

-

got10carz

Topic author - Posts: 497

- Joined: Sun Jan 06, 2019 6:37 pm

- First Name: Steve

- Last Name: Meixner

- * REQUIRED* Type and Year of Model Ts owned: 1911,13,14,19,23,25,26,27

- Location: Moorhead MN

- MTFCA Number: 28023

- MTFCI Number: 20471

Re: A Crank in T. Practice

Back from Chickasha, thought I should answer Davids question. I shortened the crank myself, ground to A size. I do plan to use the B cam. I have 2 different blocks going together, 1 flathead, 1 for a overhead.