Page 1 of 1

Machine shop (lathe) Oregon

Posted: Mon Dec 13, 2021 5:13 pm

by Tlitwin

Looking for recommendations of a machine shop that can work on transmission drums in the Portland Oregon area.

Thanks Tom

Re: Machine shop (lathe) Oregon

Posted: Mon Dec 13, 2021 5:17 pm

by Allan

Tom, if you are looking to clean up the friction surface on the drums, a better result comes with grinding them rather than machining them. Grinding gives a much finer surface finish. the machine shop I use does drums on their crankshaft grinder.

Hope this helps,

A llan from down under.

Re: Machine shop (lathe) Oregon

Posted: Mon Dec 13, 2021 5:47 pm

by Scott_Conger

If the machine shop is not a "T" shop, you may very well end up with beautiful but broken drum(s) after the 2nd or 3rd assent/descent of a tough hill.

Removing material is not always necessary...bands will conform to excursions created by rivets without any extra help, and there is precious little extra iron to sacrifice to anything other than a band in normal use.

If grooves in drums really upset you, invest in new drums (cry once and then enjoy your car for the rest of your life).

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 3:42 pm

by George House

I would think the best machine shop in the Portland OR area to grind (like Scott says) those tranny drums would be found in the Spokane Valley under the ownership of Rick Carnegie.

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 3:54 pm

by RajoRacer

Check in with Scott Hills in the Hillsboro, OR area - he can point you in the right direction !

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 3:57 pm

by J and M Machine

Tlitwin wrote: ↑Mon Dec 13, 2021 5:13 pm

Looking for recommendations of a machine shop that can work on transmission drums in the Portland Oregon area.

Thanks Tom

Make sure they can clean and crack inspect them first. !

The picture enclosed is the reason we started making new drums and hubs as what was is available wasn't to our standard nor to Ford's.

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 8:42 pm

by T Cruiser

Contact Steve Tomoso in Tacoma ,he can regring the surface and balance drums.

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 10:04 pm

by RajoRacer

Thanks for the plug Ted - my machine shop buddy retired & sold his crankshaft grinder/polisher - Scott's closer to the o.p. than I am !

Re: Machine shop (lathe) Oregon

Posted: Tue Dec 14, 2021 10:37 pm

by Steve Jelf

What J&M said. Many original drums have cracks, often hard to see. Reverse drums especially seem to be problematic, but lots of the others are cracked too. That's why my busted low drum will be replaced by a new one from Dave Nolting.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 10:40 am

by RajoRacer

I also magnaflux.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 11:34 am

by henryford2

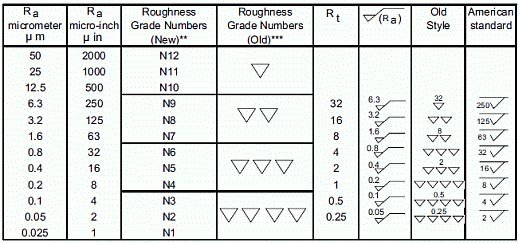

Is there a surface finish (micro finish) recommendation (Ford drawing) for the drums? Could it be different for softer bands (cotton) versus harder Kevlar?

- SurfaceFinishGradeRoughnessNumbers.jpeg (57.89 KiB) Viewed 3639 times

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 12:16 pm

by Scott_Conger

Someone will have a drawing, and I'll bet there is no surface finish call out that equates to modern measurement systems (if any at all). In reality, a 32Ra or 16Ra finish is fine. 16 being a bit of overkill.

With the correct tool and surface speed, lathe turning is absolutely fine if you know what finish you are seeking. If you just whale away at it with the wrong tool or speed, you'll end up with a decent looking finish which will be murder on the linings. Grinding is a little more fool-proof, but not mandatory. Turning them is what I do on the rare occasions I feel I must, and I've never had a problem.

Herm Kohnke, (love him, hate him, or ignore him), used to produce very nice drums from worn originals (not new) and very high quality work on a very humble lathe setup, so don't take my word for it, seek out some of his posts on this subject.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 12:50 pm

by J and M Machine

Scott_Conger wrote: ↑Wed Dec 15, 2021 12:16 pm

Someone will have a drawing, and I'll bet there is no surface finish call out that equates to modern measurement systems (if any at all). In reality, a 32Ra or 16Ra finish is fine. 16 being a bit of overkill.

With the correct tool and surface speed, lathe turning is absolutely fine if you know what finish you are seeking. If you just whale away at it with the wrong tool or speed, you'll end up with a decent

looking finish which will be murder on the linings. Grinding is a little more fool-proof, but not mandatory. Turning them is what I do on the rare occasions I feel I must, and I've never had a problem.

Herm Kohnke, (love him, hate him, or ignore him), used to produce very nice drums and very high quality work on a very humble lathe setup, so don't take my word for it, seek out some of his posts on this subject.

Just a slight correction Scott: Herman Kohnke never made drums. Herman Harder did until he died . We make the drums and gears as a unit that all the dealers sell.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 1:16 pm

by Tlitwin

Thanks everyone for all the information. I am definitely going to have the drums checked for cracks as I already have a few that have been scraped as the cracks are very visible.

Tom

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 3:10 pm

by Scott_Conger

J&M

that was a good call out...I did not mean he made them new, just that he reworked old drums to a very high degree of finish by turning. I reread my original post, saw that I typed a very misleading statement and just now have revised it to read as I originally meant/intended.

Many thanks for that and sorry to you and anyone else who did not understand what I so unclearly typed...it's all fixed now.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 3:30 pm

by TXGOAT2

New drums would be preferred, since there's no way to know what manner of use/abuse old ones have been subjected to. There isn't much material on the drum face/rim to begin with, and making it thinner will make the drum more prone to crack in at least 2 different ways. A thin rim will heat up very quickly over the holes and less quickly over the "spokes", which sets up uneven expansion and stresses. A drum in that condition would probably work OK in very light service, but crack easily under normal or demanding sevice. About any service in today's world is demanding on the brake drum.

Re: Machine shop (lathe) Oregon

Posted: Wed Dec 15, 2021 3:34 pm

by henryford2

There is an overlap in the Ra finish possible for either lathe turning and grinding. 32-16 is possible with lathe turning. Easier to find someone who can turn your drums rather than grinding.