Page 1 of 1

Torque up cylinder head

Posted: Sun Jan 23, 2022 9:02 pm

by TonyB

I have a Z head on the 14 touring and have just completed a valve job. As I remember iron heads are torqued down when cold after a heat cycle for three or four times. However aluminum heads are torqued when hot.

Is this correct?

So I might remember next time, why is this?

I know the difference inp expansion rates and understand the need for repeated treatment but why the difference between aluminum and iron head?

Re: Torque up cylinder head

Posted: Sun Jan 23, 2022 9:36 pm

by DanTreace

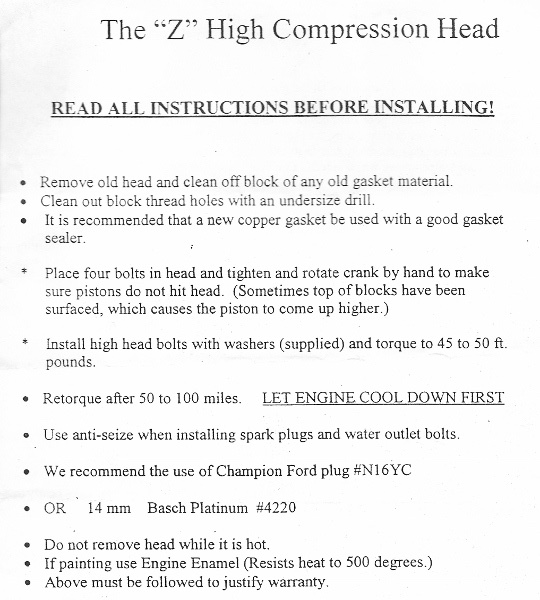

Let the engine cool down to re-torque the original bolt tightness of an aluminum head after running. Don't re-torque a hot alum head, for expansion reason. And don't remove a hot alum. head, it can warp when cooling.

- 345422.jpg (135.16 KiB) Viewed 3189 times

Re: Torque up cylinder head

Posted: Sun Jan 23, 2022 9:52 pm

by Norman Kling

Iron head: Torque cold then warm up the engine and re-torque.

Aluminum head: Torque cold then after you warm it up, let it cool down again and re-torque.

With either type head, do this a few times until it holds it's torque and ready to drive.

Norm

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 10:57 am

by RajoRacer

I've installed several dozen iron heads and never re-torqued one warm or hot. Initial torque sequence to 40 + lbs., start engine, get up to normal operating temperature then let completely cool, usually a couple start & cool re-torque cycles will suffice to hold the torque steady.

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 12:20 pm

by Jerry VanOoteghem

RajoRacer wrote: ↑Mon Jan 24, 2022 10:57 am

I've installed several dozen iron heads and never re-torqued one warm or hot. Initial torque sequence to 40 + lbs., start engine, get up to normal operating temperature then let completely cool, usually a couple start & cool re-torque cycles will suffice to hold the torque steady.

I have installed several heads, iron & aluminum, and have ruined several gaskets by not re-torquing. I torque to 55 ft-lbs and usually find that after a heat cycle, the bolts are then at about 35 ft-lbs. Re-torque to 55 & recheck...

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 12:30 pm

by TXGOAT2

I think Rajo meant not retorquing while hot. (?) As in: Initially, bring up to full torque in stages, cold. Run engine to running temp, shut down, let cool, then retorque. Repeat as necessary to stabilize torque.

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 1:02 pm

by RajoRacer

Yes, that was what I was implying but I do not torque over 45 lbs. whether iron or aluminum & I've installed plenty of both. One needs to consider the length of the Ford spark plug/head bolt, rim nut wrench - I don't believe you can pull that to any where's near 55 lbs.

I know there are 2 camps as far as torqueing hot or cold - I'm in the "torque when cooled down" camp !

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 1:14 pm

by TonyB

ThAnks guys

I guess both are torqued cold after a heat cycle.

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 4:09 pm

by Norman Kling

With the iron head, both the head and the block will expand at approximately the same rate, so It would not make as much difference if you torque hot or cold, however, with aluminum, the aluminum expands more than the iron and it will get tighter as it heats up, so it will test tight when hot, but could actually be too loose when cold. So with aluminum be sure to torque when cold.

Norm

Re: Torque up cylinder head

Posted: Mon Jan 24, 2022 5:21 pm

by Art M

Make sure the headbolt threads and bolt head shoulders are clean and dry. Do not use oil, particularly with an aluminum heads. I like 40 to 45 ft-lb with aluminum. The bolt tension greatly increases with heat.

Art Mirtes