Page 1 of 1

Resurrecting a Green Engineering Equipped T Racing Engine

Posted: Wed Feb 02, 2022 4:49 pm

by David Greenlees

I'm looking for information about a 122 C.I. sleeved short block built in the period that has appears to have Green Engineering sleeves, a Green chrome-nickel timing gear, and a cam possibly re-ground by Green with 5/16" lift and different intake and exhaust profiles, and lightweight 1-3/4" racing valves.

These engines and parts were made available so that lightweight Ford racing cars with a smaller bore of 3.437 (3-7/16") could compete under the new 1920s AAA rules mandating a smaller engine size no larger than 122 CI. The standard Ford engine size was 177 C.I. with a 3.75" (3-3/4") bore size.

The full-circular counter-balanced crank of the type, which Green offered at the time is in this engine and has 1-5/8'" mains and 1-3/8" rod journals. It has balanced T rods bored out to the rod bolts and re-babbitted and fitted with 2-ring 4-7/16" Green Aluminite aluminum-nickel pistons. The engine is not an overhead and remains an L-Head and the cylinder head is missing but presumably was equipped with a Green 122 C.I. racing head. I will share photos of the block, cam, and valve train soon.

In the meantime, I'm looking for images or illustrations showing the right and left-hand sides of a 122 C.I. Green engine. The photos are needed to determine the original routing of the extra water lines that cool the bottom of the sleeved cylinders, and determine what type of intake, exhaust manifolds, and carbs were used by Green on their non-supercharged engines.

Re: Green Engineering Equipped and Fronty S-R Racing Engines

Posted: Wed Feb 02, 2022 5:23 pm

by Henry K. Lee

And people call me nuts for bull nosing the mains of a new crankshaft! Will do some searching in my records tomorrow.

Hank

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Wed Feb 02, 2022 6:42 pm

by Shane Lach

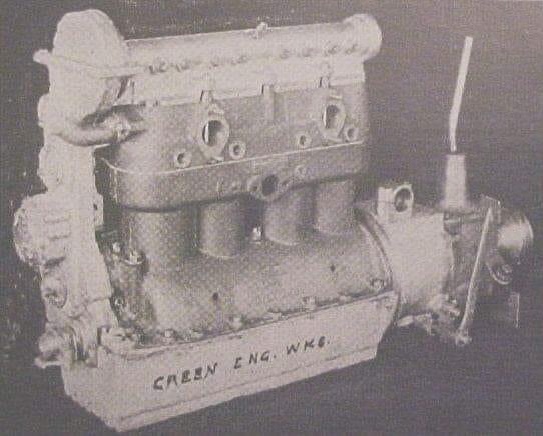

- 605DE9AD-DDEE-4A60-AB7C-3AE273697E4F.jpeg (80.3 KiB) Viewed 5497 times

Unfortunately this is all I have. Tim Moore May shed some light on this.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Wed Feb 02, 2022 7:29 pm

by David Greenlees

Shane Lach, Thanks for posting that photo, I'm always delighted to see any Green Engineering photos and hope others will post anything they have on the subject.

The engine we have is an L-head racing engine which is sleeved down to 4-7/16" like what is see in this ad copy and has an identical light weight 1-3/4" racing valve with larger stiffer springs. I recently saw one of these flathead engines in a Green "Super Ford" racing car illustration.

Green also offered an identical head with a larger combustion chamber for use on a standard Ford engine. I'll post more photos tomorrow.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Wed Feb 02, 2022 7:30 pm

by Les Schubert

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 12:52 pm

by David Greenlees

This 1924 photo we found last night in a page of Green's "Super Ford" racing car and parts list, answers our question about what Green Engineering used for intake and exhaust systems on their non-supercharged flatheads. Stub exhaust pipes and either two updraft Master or Zenith racing carburetors.

The rectangular intake manifolds appear to be the same shape as the modified intake ports in our cylinder block. And the side profile appears to raise, curve and fall in a sideways J shape. "Pops" Green may have used this shape after seeing the success Winfield had with his flathead manifold?

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 12:56 pm

by David Greenlees

Les Schubert wrote: ↑Wed Feb 02, 2022 7:30 pm

Les, have you progressed with this 5-main block and crank project which is the answer to all bearing problems in a T? Did you make the patterns for this block?

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 2:23 pm

by John bevardos

spark plug over the piston ....looks like the lizard speed head from years ago copied that.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 2:47 pm

by David Greenlees

John bevardos wrote: ↑Thu Feb 03, 2022 2:23 pm

spark plug over the piston ....looks like the lizard speed head from years ago copied that.

And Green, an SAE Engineer adopted the Ricardo squish band on the left side that promotes turbulence in the combustion chamber which mixes up the air-fuel mixture to a greater extant just before the plug fires.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 2:57 pm

by Les Schubert

5 main block; I have the patterns for it and a small quantity have been made. You can buy the patterns. I will not be making any more.

The spark plug above the piston on a flathead idea was discarded in the late ‘30’s when they realized that a wedge combustion chamber was superior on all designs except the Hemi.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 3:41 pm

by David Greenlees

Les Schubert wrote: ↑Thu Feb 03, 2022 2:57 pm

5 main block; I have the patterns for it and a small quantity have been made. You can buy the patterns. I will not be making any more.

Did you make these patterns or did they come from Zakria's Garage in OH?

I don't blame you for not wanting to make anymore blocks. I've also made lots of castings like you have and made a new 1915 Duesenberg 16-valve four block and a set of three Packard blocks for a 1913 six. All of them worked out fine but dealing with foundries, and all the work that is involved gets old.

Re: Fronty S-R and Green Engineering Equipped Racing Engines

Posted: Thu Feb 03, 2022 4:53 pm

by David Greenlees

This view of the right side of the block shows the rectangular openings to the intake posts which match up with the rectangular intake manifolds in the photo below.

The rest of these photos show the complex added Green cooling system: The outside of the sleeves are shaped somewhat like the outside of an old wooden spool of thread with "flat rims" top and bottom. In between top-to-bottom, extra added water flows in from the holes in the bottom of the outer cylinder wall and cools of most of the length of the sleeve just like modern cylinder walls are, for even cooling without distorted cylinder walls when up to temp and running. This leads to a better piston ring seal and less scuffing of the cylinders and piston and the result is added power.

This may only add a a few extra HP but it all adds up and can be the difference between winning and losing a race. "Pop" Green was a brilliant engineer and it shows in the designs he came up with and his shop built and sold to racers.

There are cutouts near the top of the sleeves thru the original cylinder wall to let the added sleeve cooling water back into the water jackets. This one is at the back of the block and there are similar holes in the other three cylinders. Look down into the water jacket to see it.

View of the sleeves and the bored out ports for the large 1-3/4" valves. Note the narrow 1/16" wide racing valve seats.

Four holes for extra cooling water are visible at the bottom of the cylinders. There are also two large inspection holes tapped for inspection plugs. The three holes halfway up the crankcase wall are for a fitting that introduces pressurized oil from the oil pump to the center and rear main bearings. One more identical hole in the front of the crankcase wall supplies oil to the front main bearing.

And finally, this is one of the holes for the extra added cooling water, and the gap between the original cylinder wall and the sleeve is visible.

Has anyone seen this same set of pattern of holes for the oil and water feeds on the left side of the block on a Green engine before?

Re: Green Engineering Equipped Racing Engine

Posted: Thu Feb 03, 2022 5:35 pm

by Les Schubert

David

The patterns were made in Calgary

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 6:10 am

by John E. Guitar

https://www.chuckstoyland.com/category/ ... g-company/

There's a lot of other great car related info on this website and its worth a look.

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 6:41 pm

by David Greenlees

John, Thanks for the heads-up, yes I found this site recently.

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 7:10 pm

by David Greenlees

The block and the main bearings and caps are now cleaned up and here's a view of the bottom end.

The manganese bronze bearing caps and the thin period babbitt is in good condition with no cracks, is bonded well with the caps and useable as is.

View of the cam - intake lobe on the left, exhaust on the right, note the different nose profiles; the lift on both is .312"

The valves are lightweight racing pieces and the 1-3/4" head is only 1/8" thick. The left-hand spring is original NOS Ford, one of the racing springs on the right. Retainers are lightweight 1/16" thick stamped steel.

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 7:44 pm

by Shane Lach

Love to see this stuff. Keep sharing please!

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 8:06 pm

by Les Schubert

My experience with a 5-/16” lift cam in a T flathead engine is that the valves float at about 4200 rpm using T springs. So I imagine that your engine will rev to about 6000 rpm.

The reduction in displacement by reducing the bore escapes me!

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 8:24 pm

by Henry K. Lee

Les, Long stroke small bore equals beautiful results! European race engines are on this model and have been for years. Super concepts.

Hank

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 10:02 pm

by Les Schubert

I missed the 122 cu in requirement in the 2nd paragraph of the original posting. Now it makes sense!

Re: Green Engineering Equipped Racing Engine

Posted: Fri Feb 04, 2022 10:53 pm

by David Greenlees

Les Schubert wrote: ↑Fri Feb 04, 2022 8:06 pm

My experience with a 5-/16” lift cam in a T flathead engine is that the valves float at about 4200 rpm using T springs. So I imagine that your engine will rev to about 6000 rpm.

The reduction in displacement by reducing the bore escapes me!

Les Schubert wrote: ↑Fri Feb 04, 2022 10:02 pm

I missed the 122 cu in requirement in the 2nd paragraph of the original posting. Now it makes sense!

Les, After piecing together all the info, statements, and photos Carl "Pop" Green published about his 122 engines, it appears that this engine shares those same specs and construction methods. If I remember correctly, he stated that his 122 would rev to about 6,000 rpm and produce 70 hp and 30% more HP with a supercharger. Arthur Chevrolet published a similar account about how high these small-bore engines would rev and stated it resulted in higher top speeds at the tracks.

Green's "Super Ford" racing car only weighed 1050 lbs, and one of these high-revving engines transformed it into a possible winner in AAA races and the ability to keep up with or pass Harry Miller's 122's on shorter tracks on the circuit.

I'll post more info tomorrow.

Re: Green Engineering Equipped Racing Engine

Posted: Sat Feb 05, 2022 5:13 pm

by Les Schubert

I am surprised at the lack of “counterweights “ on the crankshaft. It wouldn’t take a lot of machining to accomplish.

Re: Green Engineering Equipped Racing Engine

Posted: Sat Feb 05, 2022 5:33 pm

by David Greenlees

Cleaned up and inspected the deck, valve ports, and the cylinder bores today and both are in good condition and restorable. This overhead shot really gives a graphic view of the valve to bore size relationship which appears to be one of the reasons why Green got 70 or 100 HP w/a supercharger out of these small 122 CI flathead engine at 6,000 RPM because it could breathe so well.

Green attributed the lighter weight of the smaller piston and lightweight Ford rods or his Aluminite rods as being a part of the package that allowed it to rev up to 6,000 rpm; he also stated that the lower reciprocating weight of both lead to longer bearing life. Green's head itself weighed less than half of the weight of the complicated OHV and SOHC and DOHC heads on the market and being 30 to 50 or more pounds lighter than other Ford race cars was a definite advantage on the track.

Green and Arthur Chevrolet were both were fans of using the very strong and light Ford rods, which the later stated would not break under the stress of racing. That and using a very thin layer of babbitt added to bearing life which was important in the days of poured bearings. The set of bored out rods in this engine have been babbitted and bored to 1.375 (1-3/8") and balanced.

Read an interesting article about the the amazing Kay Fleischmann Special AAA 122 CI Ford-powered racing car @

https://theoldmotor.com/?p=99626. It has a Green Supercharger and more information and photos of them can be found there.

One thing I don't have for this engine is the ultra high compression squish patten Green Power-Plus racing head above. It's unlikely I'll find one since anything made by Green is very rare, so maybe modified and milled high compression repro alloy flathead will have to be used? The photo below contains the standard Green Power-Plus head. I also have a Fronty S-R engine as well as a spare head, and one of the S-R heads with high compressions pistons is an option, as well as a Rajo BBR racing head, so there are also other ways to go here.

Re: Rebuilding a Green Engineering Equipped T Racing Engine

Posted: Sun Feb 20, 2022 1:02 pm

by David Greenlees

Found an article in the Motor Age December 12, 1918, issue showing the shape of an earlier Green Ford head combustion chamber design.

And a better photo of the bottom end.

The same crankshaft in an earlier Green catalog below.

The different engine kits below.