Page 1 of 1

Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 2:54 pm

by Art M

In the early spring of 2020, I took the rear axle apart to inspect thrust washers and bearings and found solid rollers in all if the axle bearings. Prior to disassembly, I noticed there was about .025 inch of up and down play in the outer bearings. This looseness sort of concerned me.

I bought the car in 1977 and drove it until 1993. The only repairs I did was almost immediately after I bought the car.. which included tightening the rod bearings and installing new band linings. The coils were never touched during this time, but frequently got free starts.

In late 2015, a local model t club was formed which I joined. Bill Coyle helped me to get the car our of storage and to start the engine. It ran but not the best until Tim Wrenn loaned me a good set of coils. I rebuilt the engine in 2017.

From 2017 to 2019 the car was driven another 4000 documented miles

The rear axle was rebuilt prior to 1970 to my best guess, total mileage is completely unknown, but I put at least 5000 miles on it up to this time.

Upon disassembly, the axle bearings were found to have had solid rollers and were in good condition. The axle shaft was in good condition, but the outer sleeves were ridged from roller end loading I debated whether to use new solid rollers or used wound rollers.

During this time I consulted with the past Hyatt chief engineer and the expert wound roller bearing engineer during our monthly lunches. Keep in mind these wound rollers were in production until 1989. These engineers retired in 1992.. they said that without looking at anything, the bearings need at least .005 in play and probably more.

Looking at used bearing cages and used sleeves, it is apparent that there is gross bearing misalignment. This is what causes the cage looseness often seen with used bearings. The chief engineer recommended that the shaft

bending be determined analytically or imperically.

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 3:04 pm

by Art M

:Something happened that t got posted prematurely.

I chose to determine the deflection and consequent brg misalignment with arithmetic. Just the weight of the car causes gross amounts.

Bottom line is: at least .020 inch up and down play in the bearing is needed. I have to shovel snow right now, but will expand on this subject .

Ar Mirtes

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 3:29 pm

by Steve Jelf

If the original type bearings were in production as late as 1989, I have to wonder if there are some NOS replacements sitting on a shelf somewhere.

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 4:26 pm

by John kuehn

I have to think that if the original style Hyatt’s were in production until 1989 the folks on this forum would have known it years ago. Anything is possible these days I guess.

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 4:34 pm

by otrcman

Hard to believe that the Hyatt's in Model T size were still avaliable until 1989.

I'm only speculating, but it's possible that our particular size Hyatt went out of production much earlier and only some other sizes were still being produced.

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 4:38 pm

by Dropacent

When Art talks bearings, I listen.

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 5:16 pm

by Art M

I cannot say when Hyatt stopped making the model t bearings, but I do know they were making wound roller brgs

for the sugar industry up to 1989. They were originally developed for the sugar industry in the 1890's. These bearings take contamination, shock, vibration, and some misalignment.

An interesting fact is: every modelt t bearing that I have seen had alternating left hand and right hand wound rollers, but I have only seen about a dozen of them. The left hand winding machine broke down in 1940, It was scrapped because the sales had drastically declined. And they found that the bearings perform satisfactorily with only right hand wound rollers. From this, I deduce that most Hyatt model t rear wheel bearings were made before 1941.

I plan to post about misalignment, theoretical life, etc.later

Art Mirtes

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 5:53 pm

by John kuehn

Here’s probably the best forum posts about Hyatt bearings and the Model T.

http://www.mtfca.com/discus/messages/80 ... 1243973228

Re: Performance of solid roller rear whl brgs.

Posted: Sun Feb 13, 2022 6:16 pm

by DanTreace

Art

Appreciate your info on the later times of Hyatt. Seems a shame this technology is lost, as the ribbon roller bearings are the best for the Model T rear axle. Read your comments on the solid rollers and your use, but for my experience of lots of driving, and working on rear axles from Ts with what I will call limited milage, the solid rollers don't hold up.

The design of these solid rollers presents 7 rollers with 7 axles. Each little axle rotates in the cage hole, and with the flex of the T, those ends wallow out and cause the rollers to become loose. Hammering on the axle shaft is the result.

Use of flexible ribbon roller bearing of the original Hyatt design is better IMO.

Worn low milage solid rollers I have pulled.

A bit more milage on this pair posted by other.

Re: Performance of solid roller rear whl brgs.

Posted: Mon Feb 14, 2022 1:35 pm

by Art M

Thanks for the response. It's interesting to learn the details of these cars. Learn, drive and enjoy

I was aware of some solid roller bearings have 6 rollers a nf others have 8 rollers. Also, I wasn't aware of the rollers are controlled as shown in you pictures. I will examine the used bearing that I removed 2 years ago. It might be worth checking the bearings (8 rollers per brg) 6in my car, it's fairly easy to do.. Mileage is about 3200 miles.

Art Mirtes

Re: Performance of solid roller rear whl brgs.

Posted: Mon Feb 14, 2022 4:06 pm

by DanTreace

Art

Thanks too, seems the recent versions of solid roller use 7. Have removed real older ones with 6 solid rollers, these were in the inner and marked "West Germany" so they were at least decades old.

Still prefer to use original Hyatt ribbon, they have lasted, and you can find very good used ones at any T swap meet.

Nice added feature is the ribbon rollers are hollow, so lots of lube passes to the axle shaft and the Hyatt sleeve race.

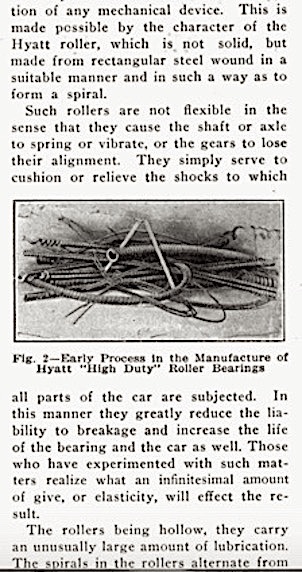

- Hyatt ribbon roller.jpg (93.09 KiB) Viewed 3963 times

- Hyatt ribbon roller stock material .jpeg (105.26 KiB) Viewed 3963 times

Re: Performance of solid roller rear whl brgs.

Posted: Mon Feb 14, 2022 7:19 pm

by Mark Gregush

Funny thing is, the Model A and V8 guys have been using the solid outer roller bearings for years. I have yet to come across anything on, for example, Fordbarn about issues with them. With modern seals on the inside and keeping them lubed, I personally don't really see the issue, esp if the axles are within tolerances, good sleeves and kept lubed.

There are only so many "good" Hyatt's out there, and considering the amount of miles most T see in a year, really don't think the solid type would hurt. I would, however, prefer to stick with the Hyatt's if I have them but would use the higher count roller solid type, if needed. The supply Hyatt's I have and people I know have, are getting very low. Of the 10 or so on my shelf, 2 might work in a pinch.

Re: Performance of solid roller rear whl brgs.

Posted: Mon Feb 14, 2022 8:09 pm

by Art M

My intent with this topic was to indicate there is an alternate to wound roller brgs. I was not trying to say that the solid design is equal or superior, but a will perform adequately. A while ago, there was a discussion about what will happen when wound roller brgs are no longer available.

Also, I guess I was trying to help the solid roller brg seller in the for sale section.

Misalignment is a big issue with the application. With 400 pounds applied upward at the center of the tire, the brg misalignment is .0038 in/in along the roller. With a thrust load of 100 lb applied at the tire OD, the misalignment is .012 in/in.

Misalignment causes roller binding and cage damage. A roller brg can somewhat accommodate misalignment by increasing the brg radial play. One way to change or control this play is to use thinner sleeves. In 2020 Langs had three thin ones in stock, the remaining stck were of normal thickness. The fourth sleeve was slightly used, which came from "Engine Joe" Bell.

Art Mirtes

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 10:25 am

by Original Smith

If the original type bearings were available until 1989, why wasn't Langs and Snyders and others selling them?

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 11:22 am

by Les Schubert

The solid rollers are fine in the middle (especially if you KNOW that the housings are straight). I won’t use them at the outside. Usually I can find acceptable wound style or I install the floating ball bearing version.

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 12:34 pm

by Jerry VanOoteghem

Original Smith wrote: ↑Tue Feb 15, 2022 10:25 am

If the original type bearings were available until 1989, why wasn't Langs and Snyders and others selling them?

These bearings were used for many different applications. Not just Model Ts. I suspect the Model T Hyatt part numbers were discontinued long before 1989.

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 12:45 pm

by Art M

Pictures of my used bearings. Tim Wrenn helped me

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 12:48 pm

by Art M

Will try later. We are in the Havana Tavern with a dozen and half members of the Firelands Timeless t's halving lunch.

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 7:06 pm

by Art M

- Picture

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 8:52 pm

by Art M

In response to several posters, picture were posted and arithmetic shows that the inner bearing misalignment more than the outer brgs.

Picture shows no wear or damage to the cages or rollers taken from my car. Thought to be 1970 or earlier.

Let's just hope that the wound roller bearing stay plentiful. Just loosen the radial play, which is a hard sell.

The pictures were taken in the dinning room while my wife was in the shower. She tolerates coil tuning in the house,, but not oily innards o21stf whatever.

Now it's time to check the condition of the wheel brgs in my car as well as check for axle seal leakage. Maybe still will be my next topic. No outer signs of oil, but I will examine inside.

Anotherpicture

Art Mirtes

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 8:53 pm

by Art M

In response to several posters, picture were posted and arithmetic shows that the inner bearing misalignment more than the outer brgs.

Picture shows no wear or damage to the cages or rollers taken from my car. Thought to be 1970 or earlier.

Let's just hope that the wound roller bearing stay plentiful. Just loosen the radial play, which is a hard sell.

The pictures were taken in the dinning room while my wife was in the shower. She tolerates coil tuning in the house,, but not oily innards o21stf whatever.

Now it's time to check the condition of the wheel brgs in my car as well as check for axle seal leakage. Maybe still will be my next topic. No outer signs of oil, but I will examine inside.

Anotherpicture

Art Mirtes

20220215_093109.jpg

Re: Performance of solid roller rear whl brgs.

Posted: Tue Feb 15, 2022 8:56 pm

by Art M

I am not familiar with floating ball bearings. It most require some modifications.

Do they float in the axial direction or float in the aligning direction.

Art Mirtes