Page 1 of 1

Question re band lining

Posted: Thu Jun 09, 2022 11:32 pm

by RGould1910

If I recall, Herm removed the center of band linings so there was a gap at the bottom. Has anyone tried this that can comment on its effectiveness and longevity? I always respected Herms advice but this one is a head scratcher. ;0]

Re: Question re band lining

Posted: Thu Jun 09, 2022 11:48 pm

by KBurket

Here is a link to his in depth post about transmission rebuild where he discusses cutting a section out of the bands.

https://mtfca.com/phpBB3/viewtopic.php?t=2114

His discussion further along in the post after the photos mentions he saw the method discussed in Dykes book.

I’m interested in folks opinions too and will be relining bands in the near future. I may give this method a try.

Re: Question re band lining

Posted: Fri Jun 10, 2022 8:53 am

by DanTreace

Seems more practical to stay with the factory way. More lining length is more friction contact, that is the purpose.

Couldn't find ref. in my 1922 Dykes to doing this to woven linings, cutting the base circle away. When you remove old woven linings the bottom part is worn too from circular contact.

- IMG_1731 (595x446).jpg (134.38 KiB) Viewed 2736 times

IMO, leave the woven lining the full length.

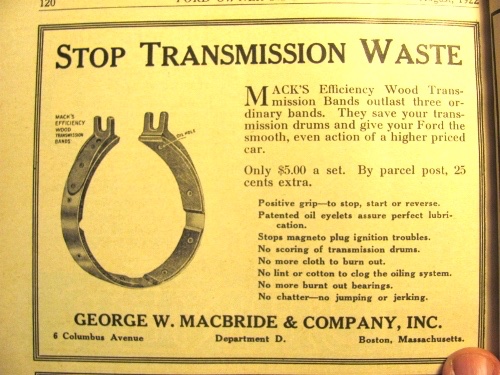

Now this segmenting likely was suitable for hard linings, like wood. One mfg. choose to make the wood linings in segments, useful to get oil to those large gaps, as the wood doesn't hold as much oil as woven linings, and useful to keep from making a whole circle of wood, easier to make.

- IMG_6615 (500x375).jpg (93.38 KiB) Viewed 2736 times

With the full circle wood linings, the ones you can purchase today, you can see that the bottom of the circle is worn thin, showing the need for full wrapping of a lining around the drum.

Re: Question re band lining

Posted: Fri Jun 10, 2022 9:31 am

by George Mills

Herm use to just pick up the phone and call me when he was bored and we'd 'porch chat' things like this. We disagreed on lots of things, but never argued.

My view of this clipped band is...depends. Even as a full professional engineer view.

Band drag is just BAD...cotton bands just wear quickly in the area of contact...wood bands might glaze and wallow...Kevlar bands at this condition raise havoc. Having that little bit missing at 6 o'clock actually near mitigates lower band drag if the metal bands are anywhere near round and not stretched to egg shape on installation.

On the other end... DRIVING HABITS. A whole lot of folks feather-in the bands against the drums, ride the feather tighter and tighter, until the drum eventually stops. BAD habit, even though wet clutch systems work perfectly well with feathering, to a degree. There is no sliding friction as such, it is actually very quick stick-slip action as there is no place for new lube once old lube is squished out! (Oh where for art thou' late Ralph Ricks?) So what happens when a resistant material is un-lubricated and no heat flushing of hot spots developed? Lots of heat, and that breaks down organic fibers, or on Kevlar just makes the hot spots hotter. Sensible people who have absolutely no issues with any band material pretty much come have a best practices approach of close to dumping the clutch pedal, using the reverse as on/off with varying throttle, and actually pump the brake pedal until almost stopped rather than drag it .

So to the original question? Notching that 6 o'clock spot lets a gulp of oil on the drum, and the following heat exchange action gets flushed away and constantly replaced.

Not saying this should be a universal consideration as I follow my own example and I'm an equal opportunity band user with the cars in the stable...no cracked drums with Kevlar, no chatter with Guinn Woods, and I'm just now running out of inventory on old original Scandia cottons. However, I can see merits in the Herm and VanDyk approach to longer band life and less drum wear, for those who are not as OC as someone like me when it comes to driving habits and insisting on absolute exact round bands with no stretching on install...

Others opinions may vary...

Re: Question re band lining

Posted: Fri Jun 10, 2022 9:42 am

by AndyClary

I’m curious how one would get adequate compression of the band material with the gap? I believe round bands and proper use are the key to band life.

Andy

Re: Question re band lining

Posted: Fri Jun 10, 2022 11:22 am

by TXGOAT2

I think band compression would be better with the gap. Pedal pressure required to stop the drum might be a little lower. I believe the gapped bands would work better on the low band and brake band, provided the installation was done correctly. I do think having a gapped brake band would make it more important to pump the pedal, that is, applying the brake firmly for a few seconds, then releasing the pedal completely for an instant, then re-applying. The gapped low and reverse bands would be a little less likely to drag, and less likely to be over-oiled, especially when cold. Pumping the brake on prolonged application would assure plenty of oil flush and good cooling. Proper installation and drums in good condition would be important, as always.

Re: Question re band lining

Posted: Fri Jun 10, 2022 11:31 am

by TXGOAT2

Keeping the engine in good tune and keeping the pedal linkage in good condition and properly adjusted are necessary to minimize slipping the low and reverse bands. A well-tuned engine will not lurch and die when the low band is applied firmly when starting the car in motion. A well-tuned engine will have good compression and low RPM torque and will be capable of a low idle speed, which improves engine braking and promotes smooth shifts from low to high at low car speeds. An engine which bucks and snorts when a load is applied makes proper use of the bands difficult to impossible. A high idle reduces engine braking and will make excess band slippage more likley, and can interfere with proper low to high shifts. Drums that are worn, grooved, burned blue, or cracked will make driving more diffcult and will eat bands. Thick, dirty oil can contribute to band engagement problems.

Re: Question re band lining

Posted: Fri Jun 10, 2022 12:55 pm

by John kuehn

Your foot decides the band life. Some drivers can wear out a vehicle by simply how they drive it. Just as true now as it was a 100+ years ago.

Re: Question re band lining

Posted: Fri Jun 10, 2022 6:21 pm

by KimDobbins

NRS and early 1909 cars used segmented linings from the factory. Just a bit of trivia.

Re: Question re band lining

Posted: Sat Jun 11, 2022 8:53 am

by RGould1910

My concern is mostly the chance of pulling a section of lining away from the band

Re: Question re band lining

Posted: Tue Jun 13, 2023 2:21 am

by Kerry

Some of the things that gave Ford grief in the first T's and changed designs to be successful for the next 15,000,000, 3 piece lining's per band, con rod dippers, X'ing babbitt and water pump.