Page 1 of 1

Ash wood substitute

Posted: Thu Dec 08, 2022 9:34 am

by BRENT in 10-uh-C

I am really struggling with my local mill who I have used for the last 10-15 years to supply me with Ash hardwood for us to use in creating body infrastructure wood. Evidently the Ash Borer has pretty much eradicated standing Ash timber in my area, so I need to either travel to purchase 6/4 or 8/4 stock, -or find an affordable ($5.00 a board ft is NOT affordable) substitute species. Traveling to get it is not really that affordable either!!

And, we typically use about 1,000 - 1,200 ft of timber a year e-wooding bodies.

Because I am getting down to about 300' left, I had him saw a Cherry log he had on the yard into 6/4 so at least I can start the air drying process, but I am definitely needing to get some stock purchased. Any suggestions on something alternate I should consider using that would be found in my area??

TIA!!

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 10:00 am

by Humblej

Same issue with beetles in Michigan. For now, ash is still readily available and affordable. I get my ash lumber and planks from a local sawmill for less a board foot than pine at the home improvement store. If I had to find an alternative to ash for body wood I would use maple, hickory, birch, and white oak.

If you want to buy over 1000 bd ft at a time I think it would be worth your trouble to travel north and buy directly from a sawmill. If you want to travel to northern Michigan I can give you contact information for my local sawmill, but there should be many sawmills closer to you than Northern Michigan.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 10:07 am

by Rich P. Bingham

As you know, ash was always the gold standard in coach building for strength and machineability. The later Model T bodies were largely framed with poplar - adequately strong, and lighter. Cherry was favored by pattern makers, indicating it's working properties are acceptable, its strength for the application is questionable.

I believe at one time the U. S. Forest Service published data on commercial timbers indicating their useful properties. A quick search there might be useful to you. Keep us posted, please ! I'm always interested in what wood-workers find economical and useful ! You're lucky to be in a region where many species of hardwoods are readily available.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 10:21 am

by Scott_Conger

From a furniture making point of view, poplar is fabulous. It is traditionally used for the unseen, unfinished parts of furniture for the last 250 years in America. It cuts, joints, rabbets, like butter... has crisp sharp edges and endgrain is almost like long grain.

It does NOT hold up to weather and is a disaster if used on house trim, rotting in less than a few years unless scrupulously sealed and painted. Any water intrusion past the finish will start to work on it immediately. Thus, it would likely be fine for interior portions of a T, but I would never ever use it in any roof structure or anything that would potentially get wet and have a mating joint that could possibly stay wet for any length of time. Perhaps old growth poplar was more robust, I don't know.

Brent, you have a real dilemma there. The borer is slowly making its way across WY as well and my few ash trees will likely succumb when that happens. It is a real tragedy in multiple respects.

The floors in my cabin are hickory and are very tough and I wonder what board/ft cost is of that? Hickory is lousy to nail and prone to split, but you will be drilling and screwing...perhaps using a correct tapered drill with adjustable countersink from a woodworking supply to prep the joints for wood screws would be OK? I'd also think that the small nails for sheet metal would be less dreadful than what happens when you use larger nails.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 11:11 am

by TXGOAT2

I had some heavy Poplar timber under some old engines. In spite of being oily, it rotted to fragments in 3-4 years. It might as well have been cardboard.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 12:44 pm

by BobShirleyAtlantaTx

I built cabinets for years. Closed the shop around 2005. Had an inventory of red oak, white oak, maple, poplar, walnut, ash etc. The ash was the only lumber the bugs got into. Down in the stack they turned it into powder. Don’t think I could use ash in a car.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 1:13 pm

by Jerry VanOoteghem

I'd go with white oak or hickory.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 2:32 pm

by pron022020

White oak is probably the next best thing, though I use Maple sometimes. At any rate, you need to spray it with a really good epoxy all around and that will negate ant future issues.

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 3:55 pm

by Rich Eagle

I remember Charley's comments from years ago.

Charley Shaver on Tuesday, October 07, 2014 - 10:52 pm:

"Eric! that's why I don't use ash or oak, I have about 300 bodies out there using sycamore.charley".

"Ford by the middle 20s was using a lot of yellow pine.charley".

FWIW!

Rich

http://www.mtfca.com/discus/messages/41 ... 1412557456

Re: Ash wood substitute

Posted: Thu Dec 08, 2022 7:25 pm

by tom_strickling

Be careful with Sycamore. Some people a very allergic to its dust and chips. Both a skin and lung irritant to some folks.

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 9:01 am

by Mark Nunn

There are several types of mechanical properties that are published by the US Department of Agriculture. I have their wood handbook. Looking at modulus of rupture (breaking stress) and modulus of elasticity (bending), there are several hardwoods that are comparable to white ash. White ash is the strongest among ash varieties. Closest woods are:

Beech

Birch, yellow and sweet varieties

Hickory, all varieties including pecan, bitternut, shagbark, etc.

Black locust

Sugar maple

Northern red oak

Live oak (white)

Swamp chestnut

Swamp white oak

Black walnut

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 10:42 am

by Rich P. Bingham

Thanks for that, Mark ! That's the handbook I had in mind when I posted in error that information was available from the forest service.

Everyone who works with wood should have that handbook ! (and I don't

)

Besides breaking stress and elasticity, there are many other properties among species that may factor into their appropriateness for auto body framing. Machinability and paintability are two that manufacturers in the day would have considered especially, but may not be so prohibiting for the hobbyist restorer.

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 1:23 pm

by Mark Nunn

Rich P. Bingham wrote: ↑Fri Dec 09, 2022 10:42 am

Thanks for that, Mark ! That's the handbook I had in mind when I posted in error that information was available from the forest service.

Rich, you were not in error. Wood Handbook: Wood as an Engineered Material is published by:

Forest Products Laboratory

Forest Service

U.S. Department of Agriculture

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 2:05 pm

by Rich P. Bingham

Thanks for that kindness Mark. I need to see about getting a copy !

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 2:37 pm

by jab35

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 2:50 pm

by Rich P. Bingham

Even better ! Thanks James !!

Re: Ash wood substitute

Posted: Fri Dec 09, 2022 3:33 pm

by otrcman

Not mentioned yet is Alder. Alder is a hardwood which I have used for sand casting patterns for some time. It's very stable, easy machining, and really stands up to abuse by the foundry guys. I don't know about predatory insects, but I have had sand casting patterns that have been used on and off for 30 years. It's a fairly heavy wood and has always served well for me. When my Dad was re-wooding his Pierce Arrow years ago he used alder with good success.

P.S. It's relatively inexpensive as good quality hardwoods go.

Re: Ash wood substitute

Posted: Sat Dec 10, 2022 10:25 am

by J1MGOLDEN

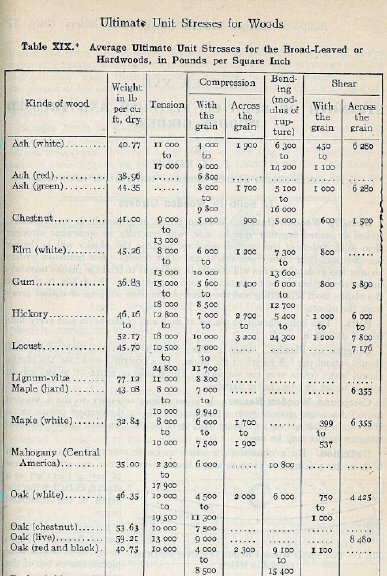

This is more information, but not a great copy.

- Wood Specs Early 20th at 72.jpg (75 KiB) Viewed 5636 times

Re: Ash wood substitute

Posted: Sat Dec 10, 2022 11:57 am

by Rich P. Bingham

otrcman wrote: ↑Fri Dec 09, 2022 3:33 pm

Not mentioned yet is Alder . . .

I have enjoyed working with alder. It machines and finishes beautifully. A drawback I encountered was its tendency to have strong internal stresses. That is, sawing a piece off of a nicely squared up plank would release internal stress to the point of binding the saw, requiring wedges to part the kerf and complete the cut; the piece that was parted off would be warped, and sometimes the parent flitch as well. This could be a function of where that particular timber was grown ? Perhaps not all alder lumber behaves that way ?

That said, dealing with this isn't insurmountable for the hobbyist, while it would be a serious drawback in production work. Once formed, items made remained stable enough in my experience, and it turns on a lathe like butter !

I question if it is strong enough for auto body framing, but it very well may be plenty strong for the application.

Re: Ash wood substitute

Posted: Sun Dec 11, 2022 12:24 pm

by MWalker

Alder is not available in 10-uh-C.

Re: Ash wood substitute

Posted: Sun Dec 11, 2022 6:01 pm

by rickg

Brent, if you haven't tried them try Jefferies Wood Works in Knoxville, they are actually in Seymour near Frank Henderson's, their number is865-573-5876 i bought a bunch of Ash several years ago from them and they have every kind of wood.

Rick

Re: Ash wood substitute

Posted: Mon Dec 12, 2022 7:24 am

by Loftfield

About those bugs: powder-post beetles, termites, other wood borers, and carpenter bees as well will get into almost any hardwood. On interior wood, such as a car body that doesn't stay outside, they can be permanently and entirely safely eliminated by mixing sodium octoborate with polyethylene glycol (note, not ethylene glycol... car antifreeze). PEG is used as antifreeze in motorhome water systems, entirely safe. Mix at 50/50 then dilute 50/50 with water, brush on, leaves no evidence of its presence other than the little nasties rub against the sodium octoborate, then die when they lick themselves clean. The PEG protects against mold and fungus, a completely win/win approach. The wood can then be successfully stained, varnished, painted, whatever. This stuff can be bought ready-made in a good hardware store, I make my own, cheaper.

Poplar was given a bad name in some posts above. It was the preferred wood for barn siding across much of the US, doesn't rot if it can dry between rains. Again, you car isn't going to sit in the rain so poplar can be safely used for car body pieces. It works very easily, takes stain and varnish beautifully, can't go wrong. I did all the interior trim in my house from a tulip poplar that was taken down in the way of the construction. The color variation in the wood gives the interior an interesting look, not stupidly boring as does wood of a perfectly uniform coloration. Maybe an artistic streak is necessary to appreciate it, I don't know.

And, we typically use about 1,000 - 1,200 ft of timber a year e-wooding bodies.

And, we typically use about 1,000 - 1,200 ft of timber a year e-wooding bodies.