Page 1 of 1

Camshaft

Posted: Sun Mar 19, 2023 2:27 pm

by Flyingpiper59

Forum Chums

I hope you all are having a great day! As many of you know, there are no new cam shafts to be had a present…. I’ve got two camshafts on back order right now ……a standard stock and a 270…. My primary objective is to have the most low end torque that I can have, because I’ve got a lot of hills to climb in the area of Pennsylvania where I live…. and in fact, my driveway is roughly at 15% grade it goes uphill for roughly a half of a mile……

Question one…… what is a stock cam grind….. roughly a 250 lift?

Question too…… which grade is going to give me the best hillclimbing….stock or 270…

Many thanks in advance and Cheers

Ed Douglas

Re: Camshaft

Posted: Sun Mar 19, 2023 2:53 pm

by Scott_Conger

the best torque is going to come from a grind which results in a slight advance of the lobes...

Chaffin's performance cams have this built in, while Stipe Cams require an advanced timing gear (1/2 tooth).

a stock .250 cam will (generally) have the best torque, while a .270 or .280 cam will (generally) give greatest top speed. Consultation with the specific mfg. is the best course to answer your question with total confidence.

A standard Stipe .280 with a 1/2 tooth advanced cam gear will take that speed and turn it into torque.... That is the combination I put into my '23 and it has GRUNT. Still starts easily and idles very well.

Contact forum member Dan McEachern and ask if he has a 7.5 degree (1/2 tooth) advanced gear on the shelf or ask him to make you one at about 5 degrees as the 7.5 may be a bit too much for your needs (ask him for advice). You won't get a better gear or advice from anyone else.

FWIW - with that long and steep of a driveway, you will do yourself a favor by setting up a good external oiler on your car if you do not already have one (and I bet you do not). A simple MAG post oiler is not up to the task...you will want a FORD Faithful type.

Re: Camshaft

Posted: Sun Mar 19, 2023 5:09 pm

by Adam

Edwin, The very first and maybe only place you should be asking this question is to the supplier or manufacturer of the cam. Cams from various suppliers are different. Current cams may also be different than ones made in the past.

Re: Camshaft

Posted: Sun Mar 19, 2023 11:08 pm

by frontyboy

With a little machine work a 4 cylinder Chevrolet will work in a model t block and give a 270+ lift. I had a old time Fronty race engine that had a 4 cylinder Chev cam and running a Fronty Sr head.

Here are the simple modifications. Remove the T cam bearings and then turn down the Chev cam shaft bearing journals to slip into the cam bearing holes in the block. The spacing of the lobes is the same as model t. This runs the cam shaft in the T block metal to metal. There is plenty of oil in that area to lubricate the cam. Lots of old time racers used this cam set up because it had higher lift and was available.

just sayin'

frontyboy.

Re: Camshaft

Posted: Tue Mar 21, 2023 3:32 am

by Mark Gregush

Model A's ran that way on all 3 bearings (5 on the early blocks) and generally have very little ware in that area. or you can do the same work to a Modal A cam.

Re: Camshaft

Posted: Tue Mar 21, 2023 12:37 pm

by Les Schubert

One further step to installing the A camshaft is that you will need to file 3 notches. Two in the front cam bearing bore and one in the middle. When I have installed them I also remove the rear bushing and just run on the block. First did this almost 50 years ago and the engine is still running great.

One other thing is that you need to “tune” the fit of the front cam cover to manage end play of the camshaft.

Re: Camshaft

Posted: Tue Mar 21, 2023 11:12 pm

by frontyboy

Found the chev camshaft that was machined to fit in a t block. It has a timing gear installed and the back of the cam is set up to drive an oil pump. I have the oil pump and the pressure lines that were installed in the Fronty engine. If you are interested I no longer have a use for it.

frontyboy 2ho6 9191949 call or text

Re: Camshaft

Posted: Tue May 16, 2023 1:07 pm

by BRENT in 10-uh-C

Les Schubert wrote: ↑Tue Mar 21, 2023 12:37 pm

One further step to installing the A camshaft is that you will need to file 3 notches. Two in the front cam bearing bore and one in the middle. When I have installed them I also remove the rear bushing and just run on the block. First did this almost 50 years ago and the engine is still running great.

One other thing is that you need to “tune” the fit of the front cam cover to manage end play of the camshaft.

Hey Les, I just got off of the phone chatting with Scott Conger and the Model-A camshaft topic came up. As a kid in the early 70's, I met a speedster guy from Turlock named Jess Blaker who was a proponent of using an A camshaft in a T block back then but as a pre-teen, I don't recall the details other than I remember him saying the block had to be notched. Jess was also a big fan of using the Vega distributor on a special plate he fabricated (-and sold) and then used a toothed timing belt to drive the distributor off of the cam.

A couple of questions regarding using the 'A' camshaft;

* Will a SCAT crank turn with clearance when using a Model-A camshaft?

* What is done to to the front of an 'A' camshaft to use a T Commutator?

* Anything needed on the rear of the 'A' Camshaft journal??

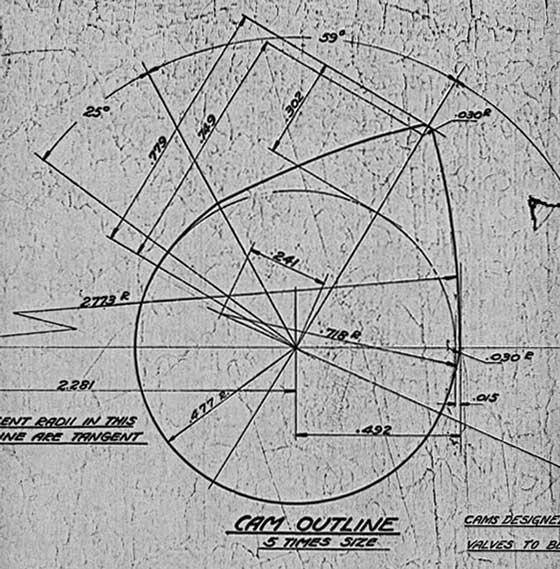

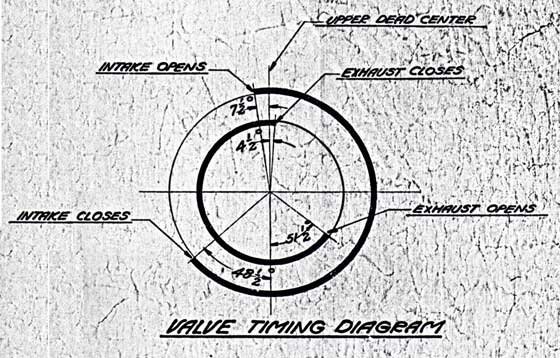

I know that a stock Model-A camshaft lift is 0.287" when it has the 0.304" lobe (-with 0.015" lash), -and the Valve Duration is about 236° with a centerline of lobe separation of about 112°, the so in a time where new camshafts are unavailable, maybe this would be very similar to the lift of the 280 Stipe Cam?? TIA!

.

.

- a6250a1.lobe.1932.08.02s.jpg (87.63 KiB) Viewed 1684 times

- a6250a1.timing.1932.08.02s.jpg (66.84 KiB) Viewed 1684 times

.

.

Re: Camshaft

Posted: Tue May 16, 2023 2:15 pm

by Les Schubert

I got into this because I found an A cam with a full race grind at a swap meet. I was building a T engine with an A crank (drilled and counterweighted). I installed the front of a T cam onto the A cam. Slotted the back to drive a VW oil pump. I built my own Vega distributor drive using a pair of helical gears. Ultimately I opened up the intake ports and then built a 4 runner intake manifold as with the cam grind I had it had very poor low rpm performance (great at higher revs!). With the 4 runner it drove nicely and reved good to 4300 rpm where the valves would float (so built in rev limiter!). 45 years later the car is still being used.