Page 1 of 1

Applying power directly to a starter

Posted: Mon Jul 17, 2023 2:50 pm

by Unprr

My Model T was converted to 12 volt before I purchased it. The previous owner hand started it during my first inspection, saying , the floor switch was defective. Once I got it home, I purchased an after market switch from Tractor Supply.

At first the starter would turn very fast and the floor switch because very warm. Now the starter will not even turn over.

My question, is it safe to apply power directly to the starter while still in the car. I’m thinking of using jumper cables to accomplish this. I Will ground to the frame and the positive to the starter.

I do have a kill switch and will disconnect the system before doing so.

Thanks in advance.

George

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 3:29 pm

by RajoRacer

You might attempt it BUT 12 volts could have damaged/locked up the Bendix drive.

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 3:49 pm

by Distagon2

As noted, your bendix could be locked up due to a bent starter shaft. Try turning it over with the hand crank to see if the engine turns over. Some years ago I fell for the advice to convert to 12 volt, and all I got out of it was a bent starter shaft. If all connections are clean and tight, 6 volt systems are just fine.

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 6:08 pm

by m_p_dean@yahoo.com

"very warm" sounds like heat, heat equals point of high resistance. That can also mean "highest" resistance relative to the current flow.

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 6:17 pm

by Moxie26

Are the battery cables "2/0" size, or thinner 12 volt cables ?..

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 8:01 pm

by tdump

I am going to mention this because I run into this alot on lawnmowers.

When applying power to a starter, Connect the positive to the terminal and use the ground to touch the mounting area of the starter for a connection. There is always a arc and that arc burns up the brass stud and nut and makes for a problem trying to get that stuff apart at a later time.

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 8:25 pm

by DickC

I converted to 12 volts about a year ago and have not had any issues. Others have warned me as well as others have said they have had no problem. It may have something to do how you use it. Always retard spark, make sure you have throttle open, and don't grind starter for long time. Seems to work!!

Re: Applying power directly to a starter

Posted: Mon Jul 17, 2023 8:38 pm

by Paradise Garage

A lot Heat in a switch usually means the switch is nfg if you are powering directly to the starter complete the last connection at the starter not the battery I blew the top off one in my 78 half ton arcing the main lead to the battery.

Re: Applying power directly to a starter

Posted: Tue Jul 18, 2023 8:23 am

by Mark Nunn

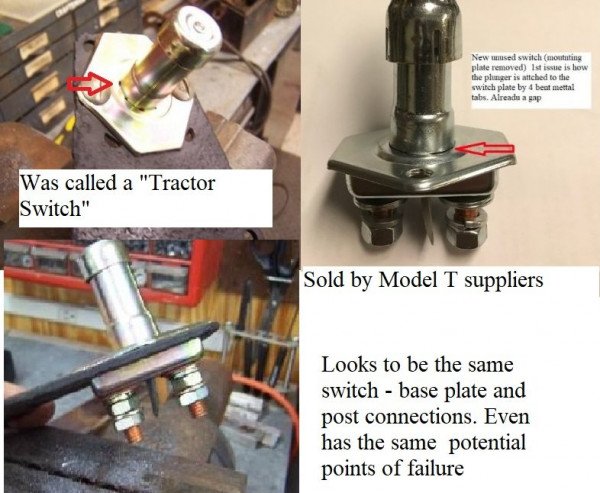

George, Tractor Supply switches are not very good. If you saved the old switch, you can rebuild it and it will be better than what you have. I know that you are not opposed to making changes so you may consider installing a starter solenoid.

Re: Applying power directly to a starter

Posted: Tue Jul 18, 2023 10:16 pm

by Unprr

Mark, if you look at the attached photos, I have installed a starter solenoid. I’m checking the wire size but believe I put in #2 .

If you can give me some direction, I’m whiling to try anything. I’m tired of Hand cranking it. Don’t get me wrong, it normally startes on the second attempt.

George Schmidt

Re: Applying power directly to a starter

Posted: Wed Jul 19, 2023 8:35 am

by Mark Nunn

If you hear a click in the solenoid when pressing the starter button and you're getting 12V at the solenoid output, I suspect the problem is the starter. I assume that all of your cable connections are as clean as the solenoid connection in your photo to support my suspicion. I think your original post and test method would be as good start to see if your starter is working.

Re: Applying power directly to a starter

Posted: Wed Jul 19, 2023 9:11 am

by TXGOAT2

If the foot switch became hot while operating the solenoid, something is very wrong.

It is very easy to test the solenoid and starter by using a short length of wire to jump the battery terminal on the solenoid to the small start terminal. Be certain the car is not in gear and that the brakes are set securely before trying this.

If the solenoid does not click, it may be defective or have a poor ground. If the solenoid clicks and the starter does not respond, the starter or a connection is at fault, or a poor ground exists between the engine and frame or at some other point.

!***** Be sure that the engine will turn over easily with the hand crank before trying anything else.****** !

Re: Applying power directly to a starter

Posted: Wed Jul 19, 2023 9:34 am

by John kuehn

I don’t know the car but if the previous owner had changed over to 12 volts could it be there were issues that caused the idea of 12 volts might be better? For me changing over to 12 volts on a stock T is akin to the reasoning of needing a water pump on a T.

And we know if the car is getting hot almost always it goes back to needing to a new radiator.

If the car could be hand cranked easily enough then why wouldn’t 6 volts do the job for a starter.

It goes back to a defective starter switch, weak battery, short in the wiring or the original 6 volt starter was the issue all along.

Re: Applying power directly to a starter

Posted: Thu Jul 20, 2023 12:31 am

by Professor Fate

Re: Applying power directly to a starter

Posted: Thu Jul 20, 2023 11:22 am

by TRDxB2

Starter solenoids with the S & I terminals for use with distributors. Ones with just the S terminal are less expensive and all that is usually needed. It doesn't really matter, just a cost issue.

The body of the starter switch is usually the problem if it is not mounted through the floor board at the proper height. Too low and when depressed doesn't make contact. Too high and eventually it bends forward and no longer is able to bridge across the studs to complete the circuit.

- sw2.jpg (66.87 KiB) Viewed 2734 times

--

--

Some questions about your wiring. I have assumed that your started solenoid switch is oriented the same as is the images I added. That is the heavy wire is connected to the starter.

I highlighted a connection to the starter switch with a green tracer & wondering where it is connected to. If you look at the schematic below it just needed to connect to the battery post on the side of the solenoid. I red ovaled the cable to the starter side, can't tell if it touching anything. What is the yellow wire on top of the photo connected to at each end?

--

You can bypass the solenoid by just connecting a jumper cable from the battery + to the starter terminal on the solenoid

--

--

Re: Applying power directly to a starter

Posted: Sat Jul 22, 2023 10:32 am

by AdminJeff

Installing a starter solenoid is a terrific investment, especially if you have a 6v car. it's literally the first mod I did when I first bought my car. I highly recommend it.

Apply 12 volts to 6v starters and they may seem to crank better but there is a hidden danger lurking. 12 volts slams the bendix into the flywheel at an amazing speed sort of like a speeding bullet into a steel plate. It is only a matter of time before the delicate bendix gives up the ghost and obliterates itself, or worse, destroys your flywheel ring gear by chipping a tooth. The worst is yet to come though. Once those bendix or flywheel parts go flying, all kinds of mayhem can ensue.

I'll attach a couple pics of what happens when you apply12v to 6v starters. I got these from various customers who all experienced multiple problems. The call I got last week was that the woodruff key was sheared off and required replacement. The starter shaft was also bent after that.

As always, your mileage will vary.

Re: Applying power directly to a starter

Posted: Sat Jul 22, 2023 4:36 pm

by Craig Leach

Jeff I'm glad you chimed in on this. Broken collars seem to be the most missunderstood part on a T starter drive. I see them welded, brazed &

staked in attemts to stop this from happening. Shouldn't the bendix nut contact the boss of the larger diameter of the shaft before the collar

collides with the ring gear? I find on most starter shafts this is in many different places. I have been machining a heavy washer to stop the drive

before it collides. At first I tryed correcting this with end spacing but have found some shafts that a 1/2" washer/spacer had to be installed. Is

there any merrit to this aproach? I do hear a noticeable quieter engagement & cranking when the collar is prevented from striking the ring gear

even the end of the starter itself.

Craig.

Re: Applying power directly to a starter

Posted: Sat Jul 22, 2023 4:59 pm

by Scott_Conger

no point in trying to convince you to retrofit to 6V and use the car as designed, but I will take this opportunity to address something that has perhaps been overlooked by everyone above:

I do have a kill switch and will disconnect the system before doing so.

This is an excellent way to kill your generator, if you isolate the battery from the generator via a kill switch and then in one way or another rig something up to start the car. Be sure your generator is attached to some battery, somewhere. POST PUBLISH EDIT: or else ground the generator output to the frame.

Re: Applying power directly to a starter

Posted: Sat Jul 22, 2023 9:08 pm

by Craig Leach

Hi George,

Scotts is correct about a kill switch. Are you talking about a battery disconnect switch that opens the connection to the battery? That will not let

you run the T without the generater connected.

Craig.

Re: Applying power directly to a starter

Posted: Sat Jul 22, 2023 10:37 pm

by AdminJeff

Craig Leach wrote: ↑Sat Jul 22, 2023 4:36 pm

Jeff I'm glad you chimed in on this. Broken collars seem to be the most missunderstood part on a T starter drive. I see them welded, brazed & staked in attemts to stop this from happening. Shouldn't the bendix nut contact the boss of the larger diameter of the shaft before the collar collides with the ring gear? I find on most starter shafts this is in many different places. I have been machining a heavy washer to stop the drive before it collides. At first I tryed correcting this with end spacing but have found some shafts that a 1/2" washer/spacer had to be installed. Is there any merrit to this aproach? I do hear a noticeable quieter engagement & cranking when the collar is prevented from striking the ring gear even the end of the starter itself.

Craig.

Honestly, I can't comment on this because I don't know. All I see is broken starter & bendix parts from 6v starters used with 12v. If you want to use 12v in your car, either buy a modern 12v starter or get a 6v starter that's been modified for 12v usage.

I've never seen broken bendix parts on 6v cars, at least that I know of...