Page 1 of 1

Commutator Shield Wear

Posted: Wed Jan 24, 2024 9:07 pm

by Boaski

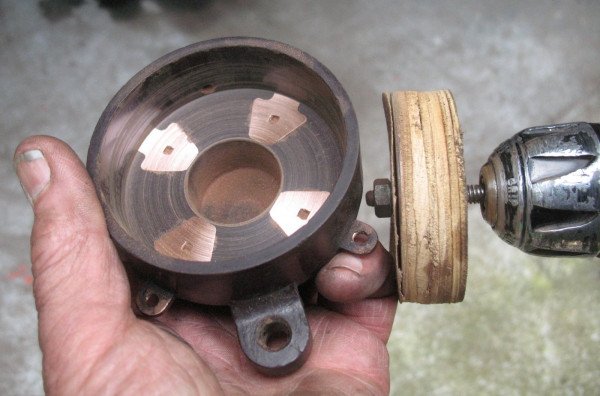

Since I have the radiator off I'm checking over stuff as it is exposed. Tonight I pulled the timer cover off and cleaned it out. I'm glad I did as I found some brass flakes in there. After I looked at the commutator shield it was pretty obvious where they came from. The timer cap seems to be OK. Is this normal wear, or is there something abnormal happening?

Re: Commutator Shield Wear

Posted: Wed Jan 24, 2024 9:42 pm

by John kuehn

Todd

Your timer is a New Day and one of the best aftermarket timers for a T. The original was a roller style timer. Since you have the radiator off now would be the time to install a modern press in seal that replaces the felt. It’s right behind the brass shield.

Using the brass shield with the New Day timer usually results in your issue.

The brush on the camshaft rubs against the shield and eventually rubs a hole in it and starts to peel away the brass. The modern seal is widely used in Model T’s and works well. You won’t need the brass shield with the modern seal.

Lang’s sells the modern press in seal for around 5-6 dollars and well worth it. Go to their website to check it out and get their parts catalog while you’re at it. It’s a great help in learning about Model T parts.

https://www.modeltford.com/item/3177OS.aspx

Use some WD-40 to clean out the timer while you’re at it. Get the copper contacts clean.

Good luck!

Re: Commutator Shield Wear

Posted: Thu Jan 25, 2024 1:52 pm

by Pep C Strebeck

I had the same thing happen to me quite a while ago, left me stopped on the side of the road. As stated above, I switched from the felt seal and brass shield to the modern seal and I have never had another problem since.

I also second the sentiment above, clean the timer. This is a photo from a past post (I believe from Steve Jelf) on how to clean/sand/reface the New Day Timer, link to the original thread,

https://www.mtfca.com/phpBB3/viewtopic. ... ng#p103066

- New day sanding.JPG (48.06 KiB) Viewed 2066 times

I had made mine out of a scrap piece of aluminum plate/sheet that was about 1/4" thick and I use double-sided tape to hold the sand paper in place. It works really well.

Re: Commutator Shield Wear

Posted: Thu Jan 25, 2024 3:40 pm

by TWrenn

I know so many people love and swear by the New Day, and I won't argue that. But I'm tellin ya if they only had or tried the TW timer from Tony Wiltshire (RIP) they may very well be as "snobbish" in favor of the TW that I am! And I've used the N.D. as most perhaps know, and had far more maintenance issues than with my TW's, and I've had them on all 6 of my Ts, coming and going. I just give 'em a quick wiping inside at every oil change and off I go. None of that "sanding disc" stuff needed. I've got over 13,000 miles on the one on my '13 and that's all I've ever done. And of course replace the brush every other year, but same said for the N.D. They're sacrificial!

Re: Commutator Shield Wear

Posted: Thu Jan 25, 2024 6:22 pm

by Boaski

Thanks for the input. That's the info I needed.

It's been almost 2 weeks since I've sent money to Lang's, so I guess it's time to place an order. I need to order an aluminum split pulley as well.

Re: Commutator Shield Wear

Posted: Thu Jan 25, 2024 6:26 pm

by speedytinc

Read the recent post about a loose pulley.

Know what you might expect with an aluminum pulley.

Re: Commutator Shield Wear

Posted: Fri Jan 26, 2024 8:33 pm

by Boaski

speedytinc wrote: ↑Thu Jan 25, 2024 6:26 pm

Read the recent post about a loose pulley.

Know what you might expect with an aluminum pulley.

I've spent some time reading through that thread recently. I'm going to give the aluminum one a shot.

Re: Commutator Shield Wear

Posted: Sat Jan 27, 2024 8:35 am

by MKossor

And should you get tired of periodic timer maintenence and replacement, the Ideal Timer is another option.

60K+ miles and still operating with the same +/- 1 deg percision and consistancy as the day installed with Zero maintenance.

Re: Commutator Shield Wear

Posted: Sat Jan 27, 2024 12:20 pm

by TWrenn

Boaski wrote: ↑Fri Jan 26, 2024 8:33 pm

speedytinc wrote: ↑Thu Jan 25, 2024 6:26 pm

Read the recent post about a loose pulley.

Know what you might expect with an aluminum pulley.

I've spent some time reading through that thread recently. I'm going to give the aluminum one a shot.

I have one on my '13 and where they even said you couldn't mount one on a narrow nose pan without removing the pan I managed to be able to do it! "No" is not in my vocabulary. I only had to shave a wee bit off the top of a rivet to get just enough clearance to slip it in..tightly. It didn't compromise the rivet at all.

Re: Commutator Shield Wear

Posted: Sat Jan 27, 2024 4:59 pm

by speedytinc

TWrenn wrote: ↑Sat Jan 27, 2024 12:20 pm

Boaski wrote: ↑Fri Jan 26, 2024 8:33 pm

speedytinc wrote: ↑Thu Jan 25, 2024 6:26 pm

Read the recent post about a loose pulley.

Know what you might expect with an aluminum pulley.

I've spent some time reading through that thread recently. I'm going to give the aluminum one a shot.

I have one on my '13 and where they even said you couldn't mount one on a narrow nose pan without removing the pan I managed to be able to do it! "No" is not in my vocabulary. I only had to shave a wee bit off the top of a rivet to get just enough clearance to slip it in..tightly. It didn't compromise the rivet at all.

The issue is good ratchet engagement.

Does your new aluminum pulley allow for good & free hand crank ratchet engagement?

Where did you get it, if it required no modification?.

Thankyou.

Re: Commutator Shield Wear

Posted: Sat Jan 27, 2024 7:38 pm

by TWrenn

speedytinc wrote: ↑Sat Jan 27, 2024 4:59 pm

TWrenn wrote: ↑Sat Jan 27, 2024 12:20 pm

Boaski wrote: ↑Fri Jan 26, 2024 8:33 pm

I've spent some time reading through that thread recently. I'm going to give the aluminum one a shot.

I have one on my '13 and where they even said you couldn't mount one on a narrow nose pan without removing the pan I managed to be able to do it! "No" is not in my vocabulary. I only had to shave a wee bit off the top of a rivet to get just enough clearance to slip it in..tightly. It didn't compromise the rivet at all.

The issue is good ratchet engagement.

Does your new aluminum pulley allow for good & free hand crank ratchet engagement?

Where did you get it, if it required no modification?.

Thankyou.

Yes it engages perfect. The bushing could sure use a replacement but that aint gonna happen any time soon! I just keep the handle firmly engaged into the ratchet mechanism. I think I got the pully from Langs, it was like 6 years ago. The only mod was like I said, because the narrow nose pan leaves little room to just "slide it on" I had to shave a slight amount off one of the rivit heads and in it went.

Re: Commutator Shield Wear

Posted: Sun Jan 28, 2024 4:42 pm

by Boaski

What years did Model T's have a narrow nose pan?