Page 1 of 1

Wristpin bolts

Posted: Wed Oct 16, 2024 12:52 pm

by ABoer

Hi all .

I just open an Engine , and see that the Wrist pin bolts are faces away from the Camshaft .

Is that a problem ??

I don't like to change that because , I like to have the Connection rods on the same place as they are now .

Thanks for your Answer .

Toon

Re: Wristpin bolts

Posted: Wed Oct 16, 2024 1:10 pm

by Erik Barrett

I always put them away from the camshaft but it really doesn’t matter.

Re: Wristpin bolts

Posted: Wed Oct 16, 2024 4:07 pm

by Kerry

As a Model T engine builder, I can tell you it is a big problem, a lot of strain on the rod clamp when fitted backwards and if you are lucky when they snap it is only the head of the bolt, the last one I fixed was unlucky and snapped the rod off and went through the block.

Re: Wristpin bolts

Posted: Thu Oct 17, 2024 3:44 pm

by Dan McEachern

Not sure how the bolt orientation could contribute to a rod failure like that but......... I'm all ears. Anyway, AFAIK the bolt orientation is just a matter of convention. I would not pull a motor apart just to put the bolts on the other side. Someday, I'll figure some of this out, but not today.

Re: Wristpin bolts

Posted: Thu Oct 17, 2024 5:31 pm

by Kerry

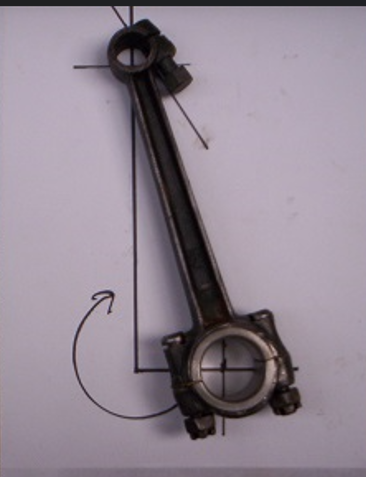

To put it simple, rods fitted with the bolt facing the cam will have the pressure points of thrust pushing on the strongest part of the rod clamp.

A rod fitted in reverse will have the pressure points pushing on the weakest point of the claw, the power stroke thrusts the piston to the cam shaft side of the bore and then reverses on the up stroke putting the pressure on the bolt, either stretching the clamp bolt, breaking the head off the bolt and even breaking the rod clamp itself.

- Screenshot (307).png (193.25 KiB) Viewed 3018 times

Re: Wristpin bolts

Posted: Thu Oct 17, 2024 8:42 pm

by John kuehn

Did the Ford engineer Murray Fahnstock or any other Ford engineers have any thing written about this? This has been brought up before. The Model T Ford service manual doesn’t mention this that I can see. Did Ford have a factory recommendation to have the engines put together? It does sound reasonable to have the wrist pin bolts in the direction Kerry says.

Re: Wristpin bolts

Posted: Fri Oct 18, 2024 1:24 am

by Kerry

The service book page 98 has after marking a rod, the markings on the rod and cap should be on the same side as the rod clamp screw. Then in the service bulletin volume 1 page 71, Assembling pistons and rods in the motor, the number markings face the camshaft side of the motor.

Re: Wristpin bolts

Posted: Fri Oct 18, 2024 6:25 am

by Jerry VanOoteghem

Kerry wrote: ↑Thu Oct 17, 2024 5:31 pm

A rod fitted in reverse will have the pressure points pushing on the weakest point of the claw, the power stroke thrusts the piston to the cam shaft side of the bore and then reverses on the up stroke putting the pressure on the bolt, either stretching the clamp bolt, breaking the head off the bolt and even breaking the rod clamp itself.

On what do you base your assumptions of the weakest and strongest parts of the con rod? It seems that this is a "seat of the pants" guestimate of what the strongest and weakest areas are. Show me some finite element analysis and we'll see the facts.

Re: Wristpin bolts

Posted: Fri Oct 18, 2024 9:58 am

by big2bird

I was always told bolts to the cam side.

Look at any illustration. They are always there.

Re: Wristpin bolts

Posted: Fri Oct 18, 2024 5:04 pm

by Kerry

Regardless on which way the rod is fitted, it is 100% reliant on the bolt, it just so happens it is more likely to fail when fitted away from the cam side. Ford even has in the service bulletin that if the bolt tension is compromised, the claw clamp will fail.

Re: Wristpin bolts

Posted: Tue Oct 22, 2024 12:38 pm

by ABoer

THANK YOU ALL for your information !!!!

Toon .

Re: Wristpin bolts

Posted: Sun Oct 27, 2024 11:59 am

by Art M

My thought is that the side doesn't matter. It is important to made sure the clamping surfaces and the threads are clean. The bolt should be torqued to about 35 ft-lb. I think the bolt size is 3/8-24. The resulting clamp load is about 8350 lb.

At 2000 rpm, the rod load at the piston pin is about 290 times the weight of the piston, pin, and rings. This occurs when the piston near the top when the exhaust is ending and the intake is starting.

Art Mirtes

Re: Wristpin bolts

Posted: Sun Oct 27, 2024 5:18 pm

by Kerry

Unfortunately, thoughts and opinions could be costly, Ford states which way a rod is to be fitted just like which way a head gasket is to be fitted, imagine how thick a service book would be if going to explain all the science of the engineering, but Ford just kept it simple to have a correct assembled trouble-free engine.

Re: Wristpin bolts

Posted: Sun Oct 27, 2024 5:21 pm

by Jerry VanOoteghem

Kerry wrote: ↑Sun Oct 27, 2024 5:18 pm

Unfortunately, thoughts and opinions could be costly, Ford states which way a rod is to be fitted just like which way a head gasket is to be fitted, imagine how thick a service book would be if going to explain all the science of the engineering, but Ford just kept it simple to have a correct assembled trouble-free engine.Screenshot (319).png

Thanks for finding and posting that!